WS-CM are the most versatile closed-case CO2 lasers, affordable and high-quality, ideal for cutting metal, non-metal materials and for engraving. Thanks to the use of an additional option, which is a rotary attachment, it can also be used to process spatial solids, which makes the laser a multi-task device in the production process. RECI laser tubes used in this series are characterized by high durability and precision. Their real service life is approx. 10,000 working hours.

See also similar models to the one being viewed:

Also check our lasers AVAILABLE

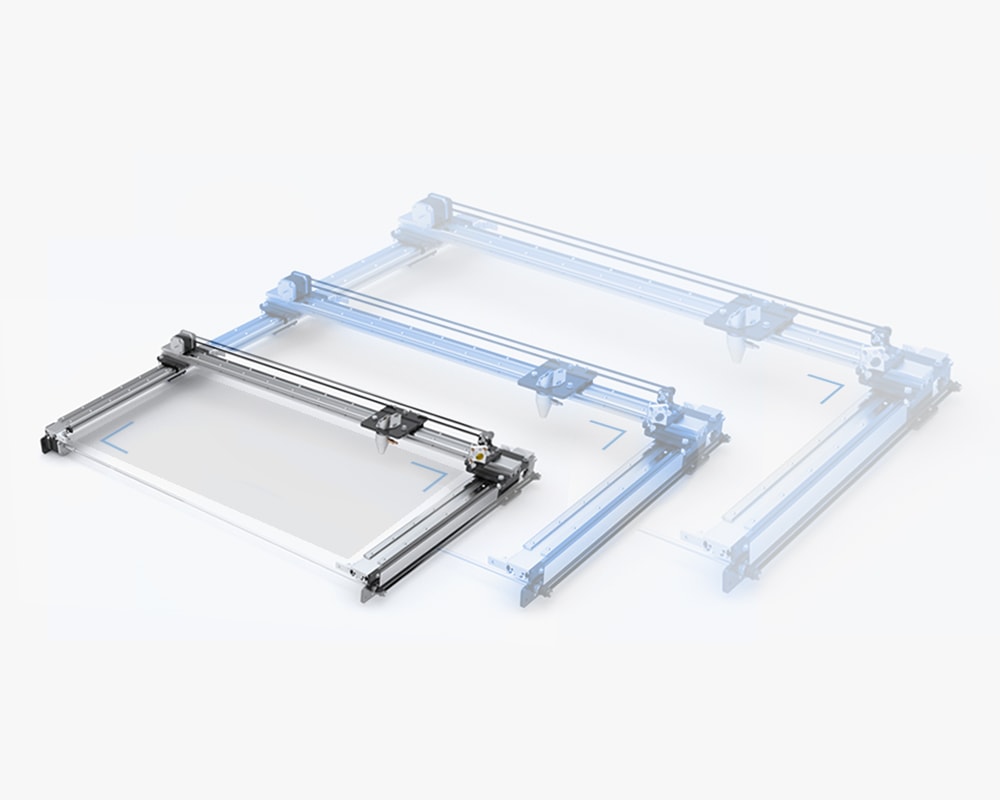

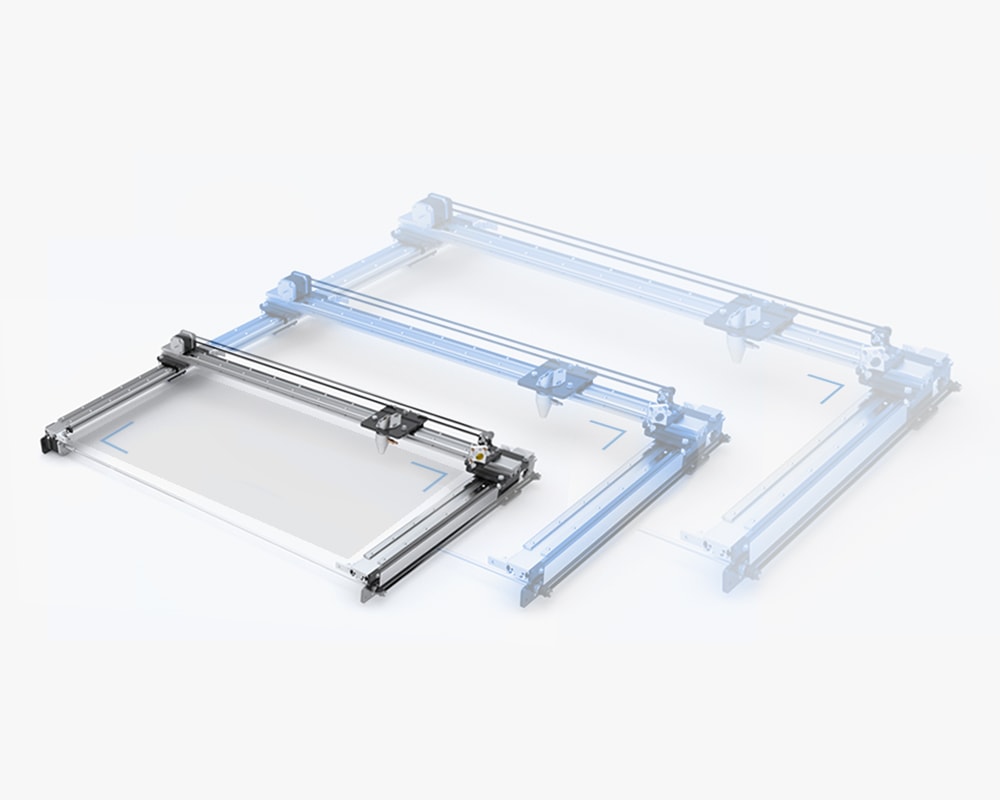

The choice of the model depends on the client's expectations, planned production, prepared budget and many other factors. The models differ in the purpose, size and type of the work table, the possibility of cutting profiles, parameters, etc.

In the case of low-volume productions, small elements and for the company's production needs, it is best to choose the table size for the most commonly cut sheets, usually these are smaller sizes. In a situation where the manufacturing company accepts orders from the outside, it is recommended to choose a larger table, in the case of a project to cut a large element from one sheet.

To cut high-reflectivity materials such as copper, brass, gold, and silver, we recommend choosing an IPG laser generator. In the case of MAX PHOTONICS and RAYCUS, there is a high risk of generator failure/damage.

Attention! It is not possible to mount the W8 tube when choosing the size of the working area of 1300x900mm and 1000x600mm!

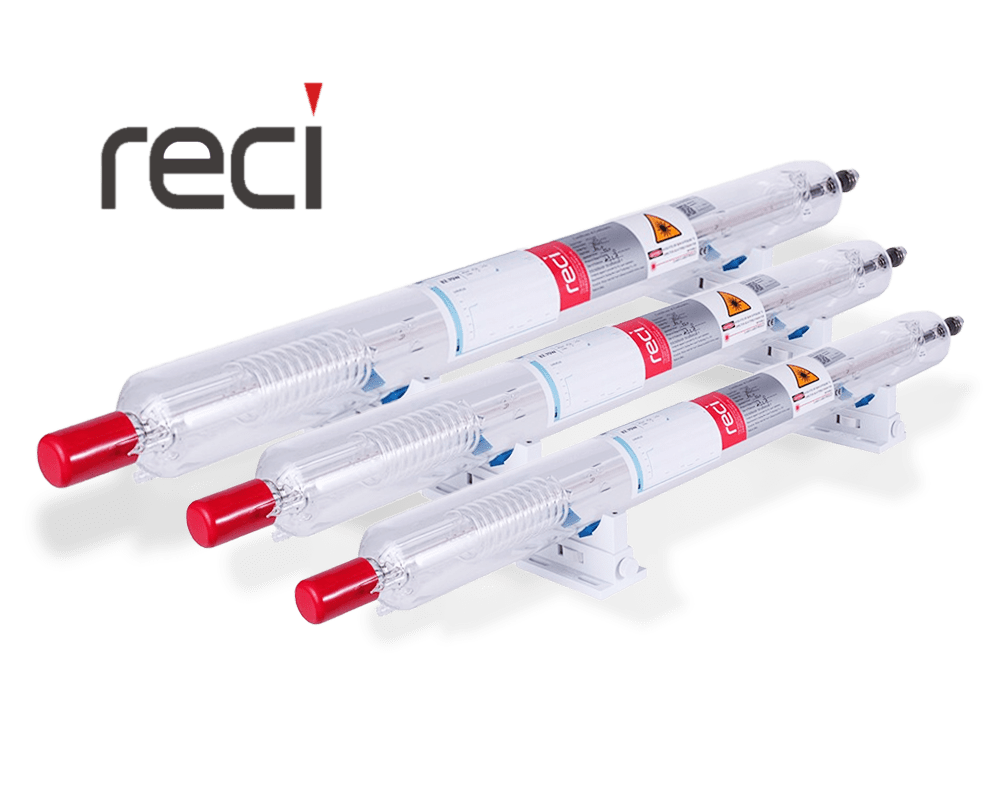

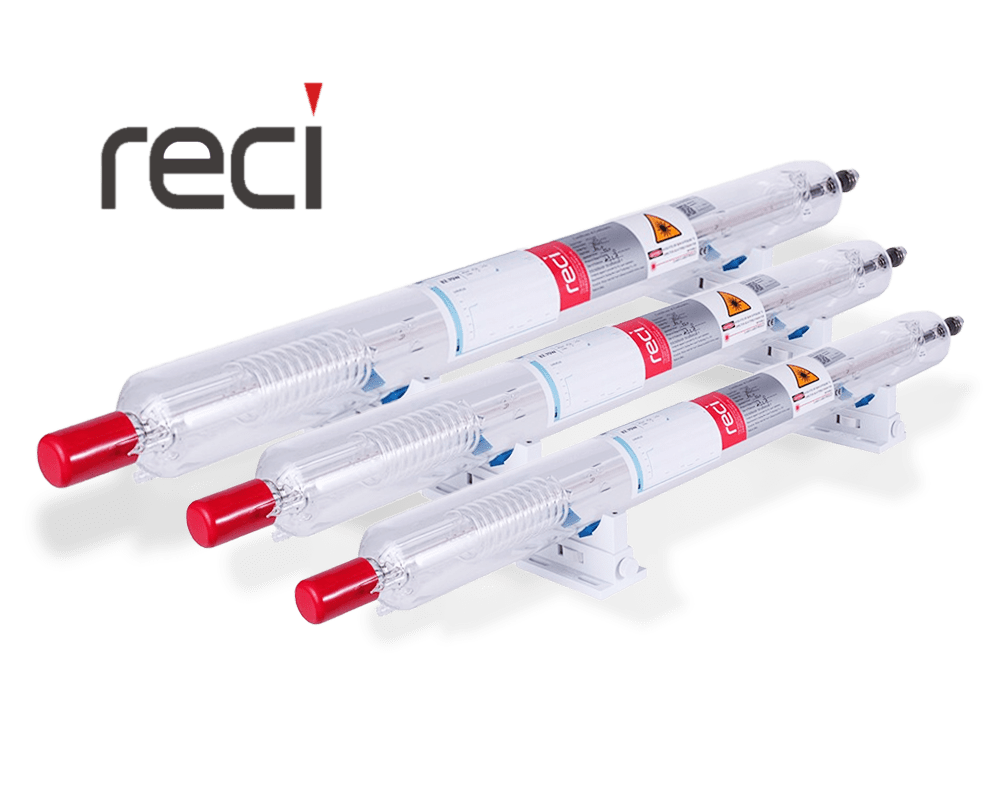

The power of the tube should be adequate to the planned production and the type and thickness of the materials to be cut. The power of the tube cannot be greatly overestimated, because precise control starts from 10% of the source's power. All our glass tubes are of the proven and reputable RECI brand, with powers from W6 to W8 RECI available in this device.

To cut high-reflectivity materials such as copper, brass, gold, and silver, we recommend choosing an IPG laser generator. In the case of MAX PHOTONICS and RAYCUS, there is a high risk of generator failure/damage.

The purchase of this service is highly recommended because provides full warranty and safe and quick installation by a qualified team, co saves time employees. During the training, all instructions are provided related to, among others: efficient operation of the device, discussion of consumables, parameter settings and the possibility of obtaining many other valuable information. Without proper training, it is easy to make a mistake resulting from ignorance, after which the repair of the device may be considered paid and not covered by the warranty.

To cut high-reflectivity materials such as copper, brass, gold, and silver, we recommend choosing an IPG laser generator. In the case of MAX PHOTONICS and RAYCUS, there is a high risk of generator failure/damage.

They provide eye protection while working on the device. Shields used in our models protect against radiation incident from any angle. Specialized glasses provide filtration in a specific range of radiation. Laser light in the range of visible and invisible radiation from 400 nm to 1400 nm also illuminates the inside of the eye. Its action causes the retina to warm up and the photoreceptors to be destroyed. Invisible radiation is largely absorbed by the cornea and lens of the eye, damaging them and leading to burns. A case is included with each glasses.

To cut high-reflectivity materials such as copper, brass, gold, and silver, we recommend choosing an IPG laser generator. In the case of MAX PHOTONICS and RAYCUS, there is a high risk of generator failure/damage.

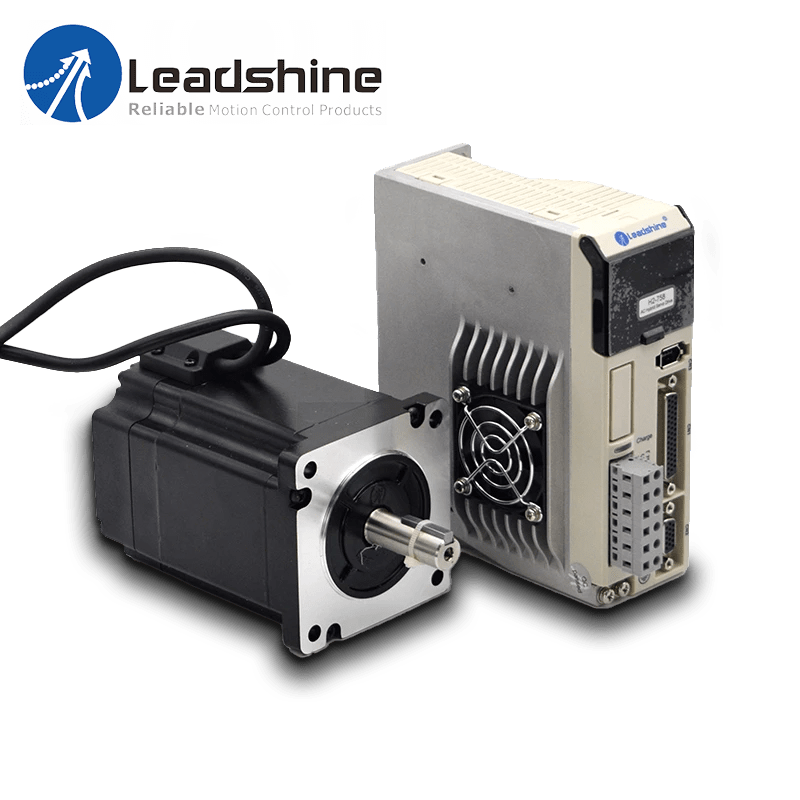

They prevent losing steps during laser operation. They ensure uninterrupted and trouble-free work devices.

To cut high-reflectivity materials such as copper, brass, gold, and silver, we recommend choosing an IPG laser generator. In the case of MAX PHOTONICS and RAYCUS, there is a high risk of generator failure/damage.

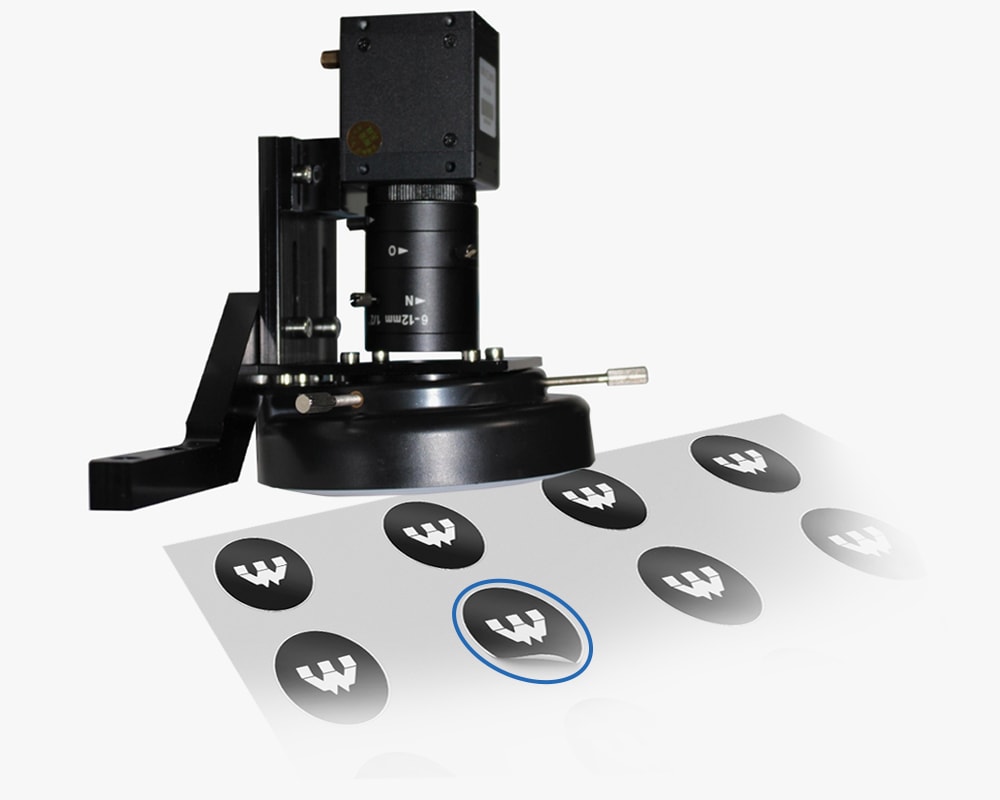

It increases the possibilities laser, allows you to cut projects along the contour.

* This option cannot be used with Autofocus.

To cut high-reflectivity materials such as copper, brass, gold, and silver, we recommend choosing an IPG laser generator. In the case of MAX PHOTONICS and RAYCUS, there is a high risk of generator failure/damage.

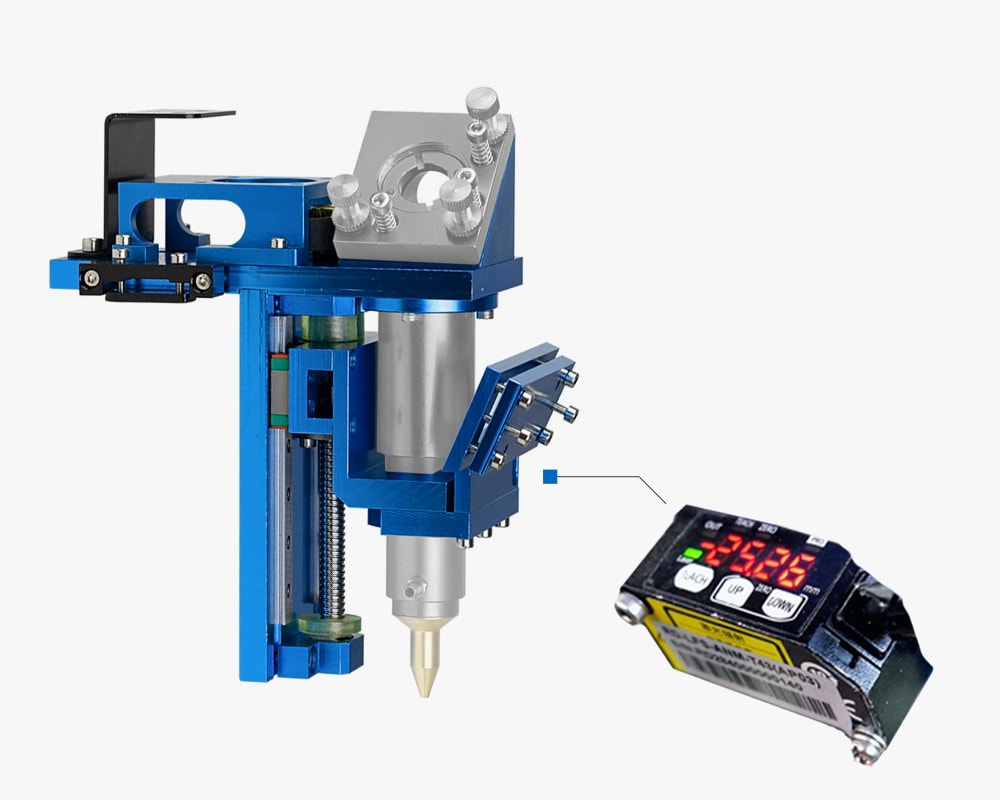

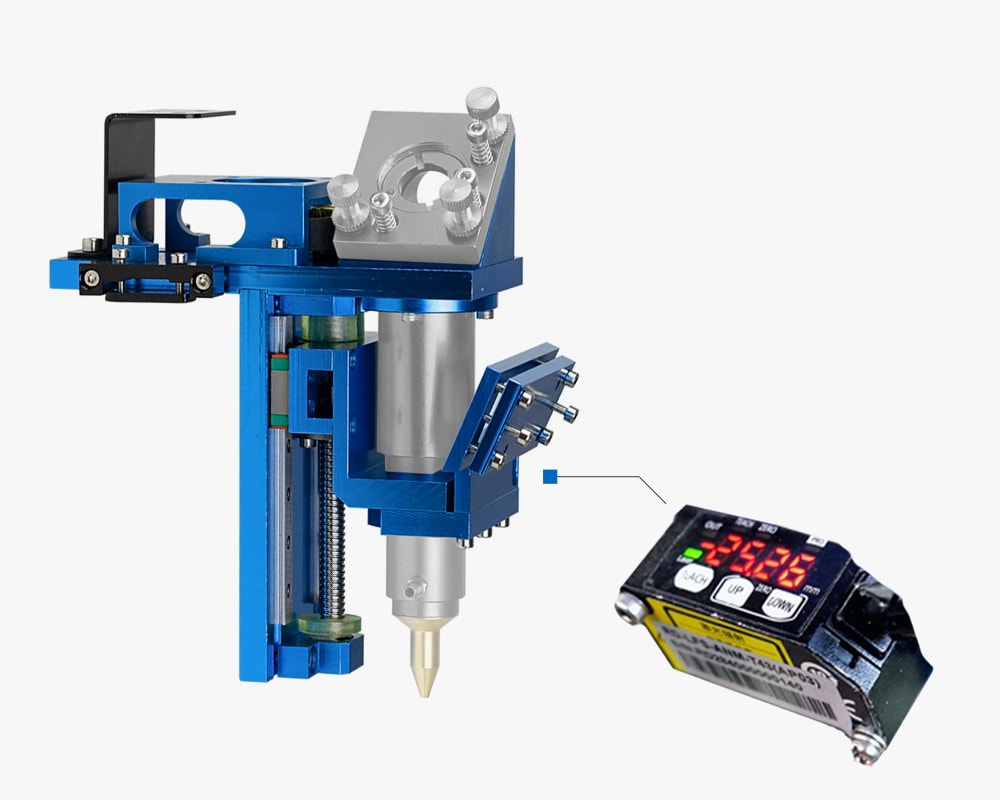

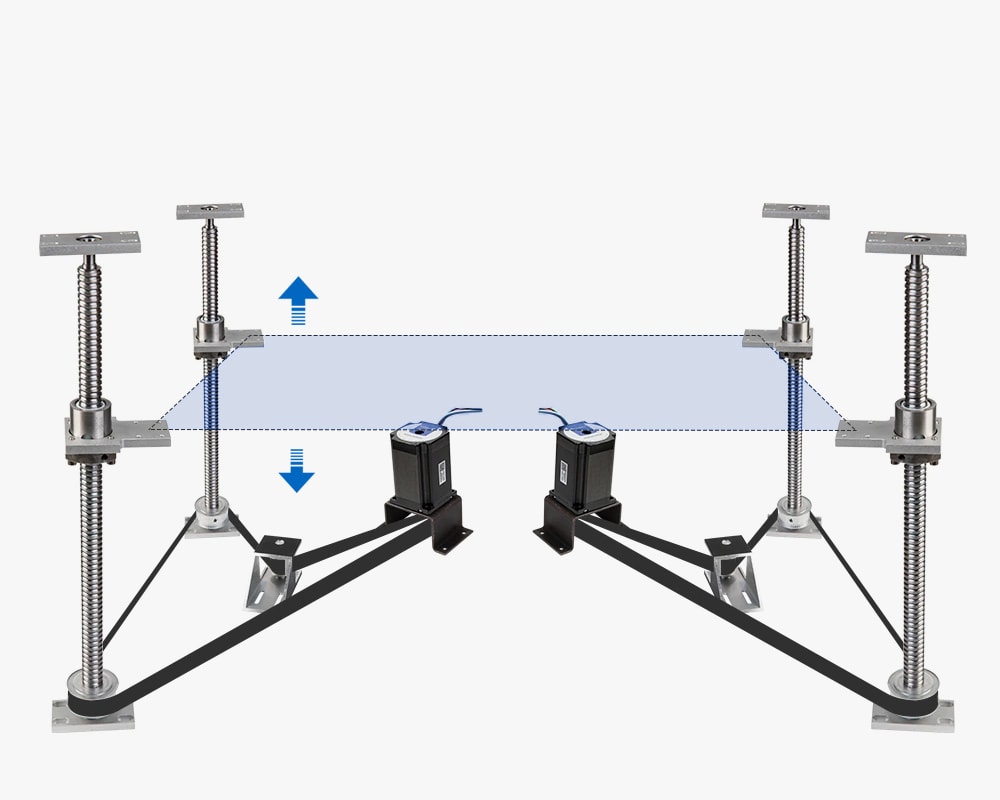

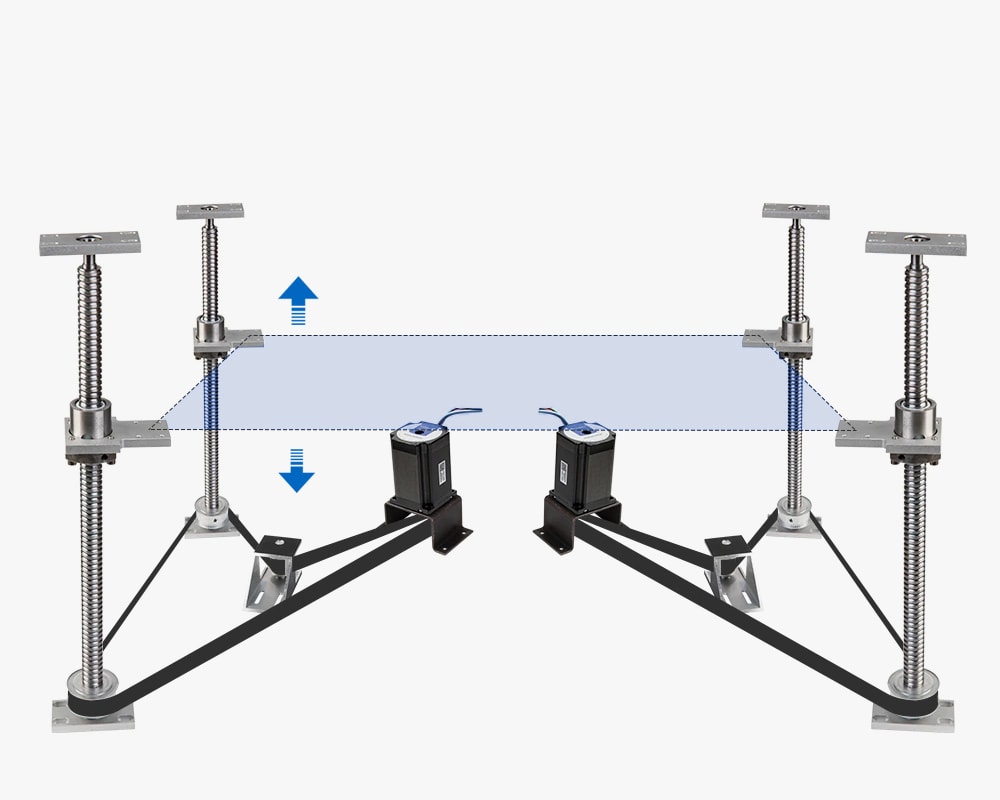

It increases the possibilities of the device because it enables cutting and engraving on spatial materials, e.g. boxes, furniture, albums, etc. Indispensable when working on materials that tend to deform, e.g. under the influence of temperature. Thanks to this option, the device automatically selects the focal length, which guarantees the highest quality cutting. Useful especially when working on materials such as fabrics, plywood, etc.

* This option cannot be used with a CCD Camera.

To cut high-reflectivity materials such as copper, brass, gold, and silver, we recommend choosing an IPG laser generator. In the case of MAX PHOTONICS and RAYCUS, there is a high risk of generator failure/damage.

It facilitates the work of the machine operators. Indispensable especially when working with large devices.

To cut high-reflectivity materials such as copper, brass, gold, and silver, we recommend choosing an IPG laser generator. In the case of MAX PHOTONICS and RAYCUS, there is a high risk of generator failure/damage.

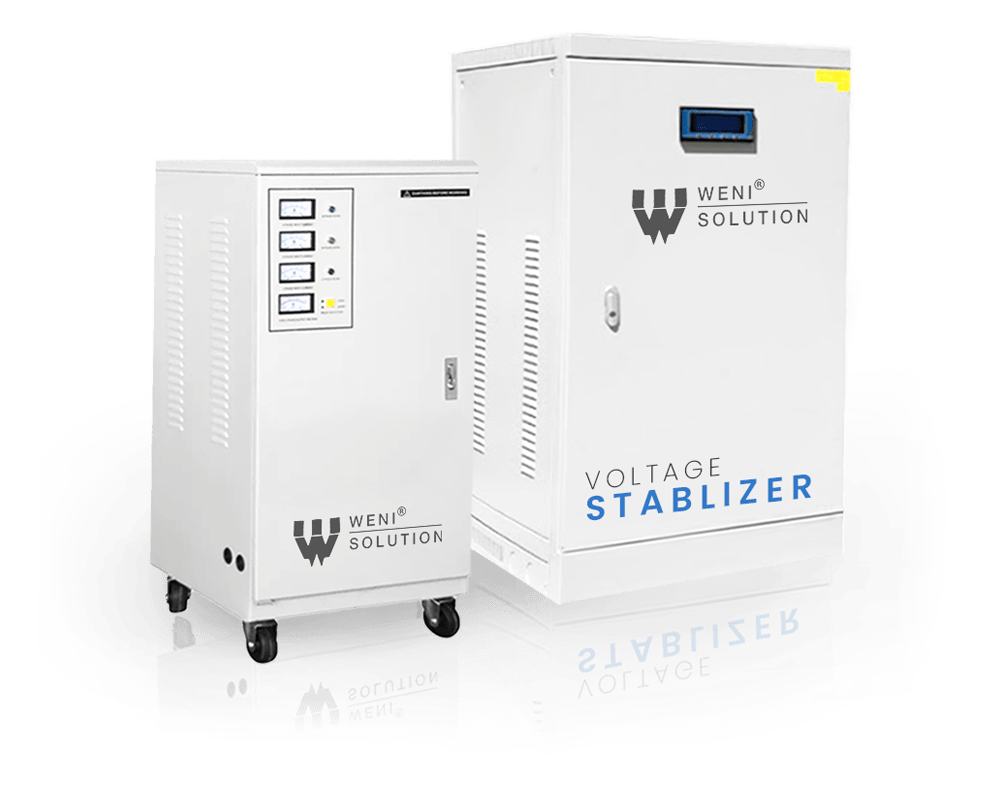

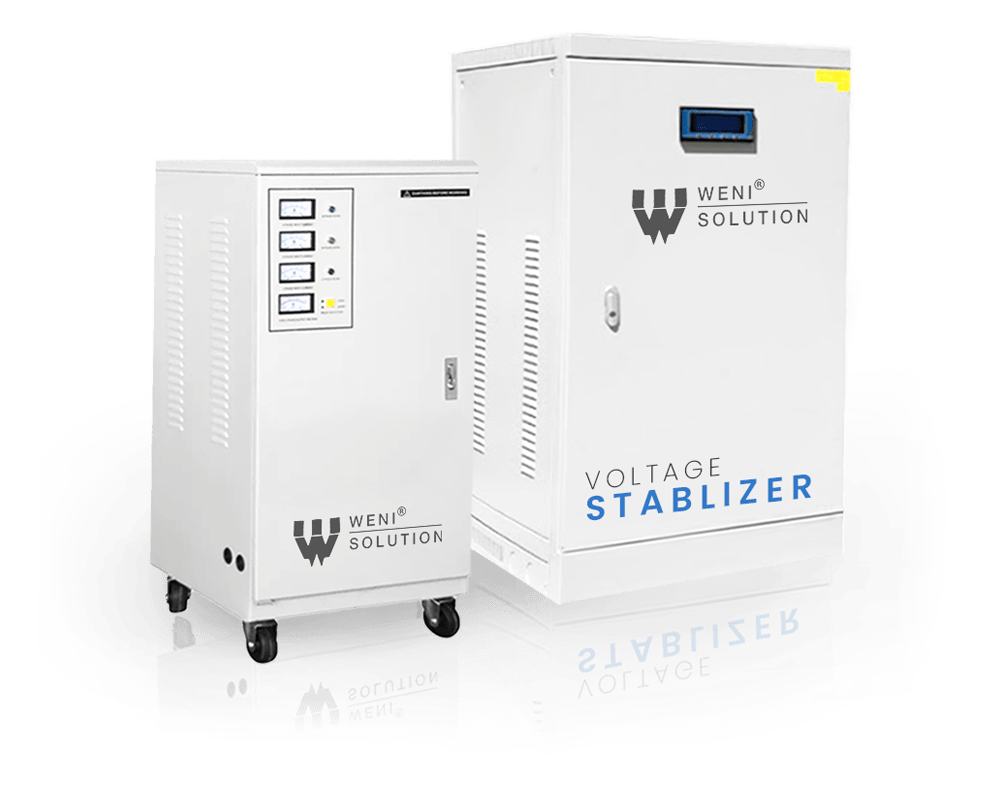

We recommend this option to everyone working with laser technology.

Apply a voltage stabilizer quickly it even eliminates long-term voltage drops thanks to the servos used.

In order for the cutting process to maintain quality, the laser cutter needs a stable mains voltage.

Large devices operating in the same network generate momentary voltage drops that may disrupt the operation of the laser.

Voltage drops can turn off the laser beam and waste material, and in extreme cases, damage the device.

To cut high-reflectivity materials such as copper, brass, gold, and silver, we recommend choosing an IPG laser generator. In the case of MAX PHOTONICS and RAYCUS, there is a high risk of generator failure/damage.

Twice the speed of the cutting process, with a slight reduction of the working area. The option of installing a second head for non-metals results from individual customer needs and projects.

To cut high-reflectivity materials such as copper, brass, gold, and silver, we recommend choosing an IPG laser generator. In the case of MAX PHOTONICS and RAYCUS, there is a high risk of generator failure/damage.

Thanks to the high torque and precise guidance, the machined edge is perfectly finished. The tool has a chip extraction system.

High-speed spindle of the well-known Japanese brand Nakanishi with a power of 360W and revolutions of 60,000 / min with full servo control - controllers, ideal for machining hard materials such as. MDF, DIBOND, ACRYLIC, PVC, RUBBER.

To cut high-reflectivity materials such as copper, brass, gold, and silver, we recommend choosing an IPG laser generator. In the case of MAX PHOTONICS and RAYCUS, there is a high risk of generator failure/damage.

Increases the capabilities of the device because it enables cutting and engraving on spatial materials, e.g. boxes, furniture, albums, etc.

To cut high-reflectivity materials such as copper, brass, gold, and silver, we recommend choosing an IPG laser generator. In the case of MAX PHOTONICS and RAYCUS, there is a high risk of generator failure/damage.

The bending machine as a peripheral device for the CO2 laser guarantees precise and repeatable bending of acrylic, which speeds up production and increases efficiency. Thanks to the multi-functionality of the tools, the user has greater flexibility in designing a variety of plexiglass shapes. Time and cost savings, as well as safe operation, are other benefits you will gain by opting for the bending machine. The specific bending machine is individually selected for the customer.

To cut high-reflectivity materials such as copper, brass, gold, and silver, we recommend choosing an IPG laser generator. In the case of MAX PHOTONICS and RAYCUS, there is a high risk of generator failure/damage.

RECI laser tubes are characterized by high durability and precision. Their real service life is: approx. 10,000 working hours. RECI tube means better beam quality, higher cutting efficiency, better quality of workmanship.

The laser Co2 RECI tube is available in various power options:

Emitted Wavelength: 10'600 nm

Cooling method: Water

High voltage excitation method: DC

Resonator Type: Glass DC

Ruid's controller - Weni Co2 lasers are based on proven Ruida components, which are a precursor in Co2 laser control solutions. The Ruida controller is the main component controlling the operation of the entire device. It ensures stable operation and a wide configuration range of Weni lasers through the possibility of adding in the option:

In the basic scope, the controller allows you to operate the laser without the use of software, where a given project can be imported directly from a FLASH / USB disk.

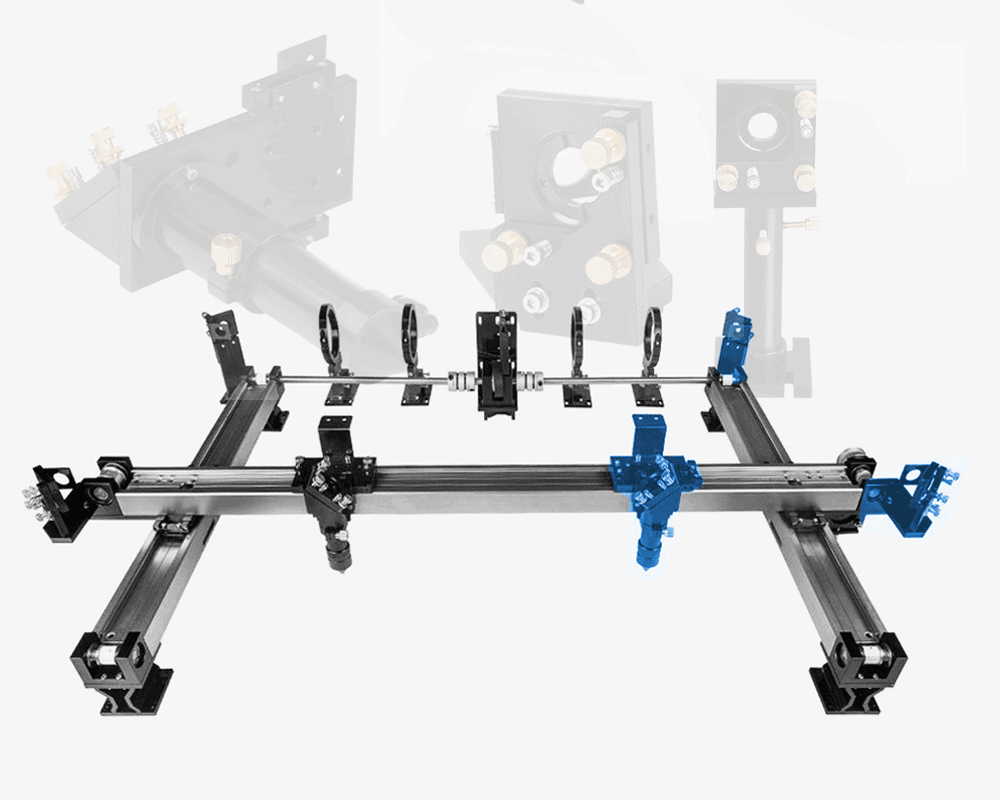

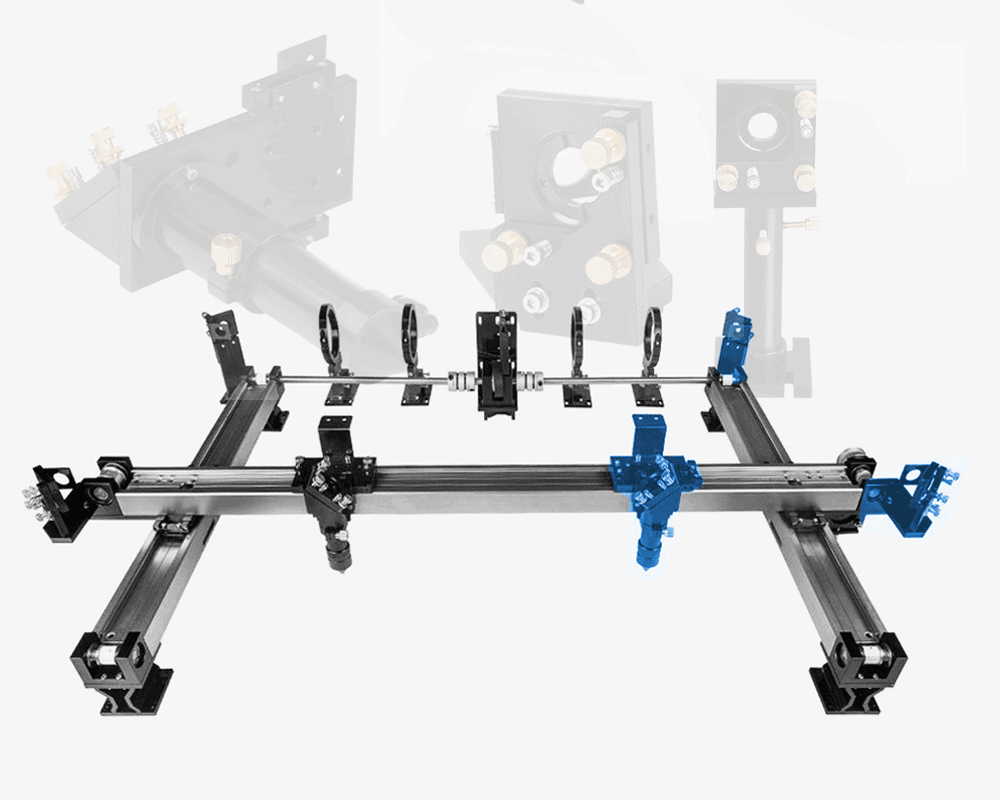

PMI / HIWIN / THK rail guides ensure high positioning accuracy, high repeatability and durability. They ensure smooth movement of the trolley thanks to the use of rolling elements - balls or rollers. The difference between static and dynamic rolling friction is very small, so that the starting force is only slightly greater than the force supporting the movement. Thanks to this type of solution, stick-slip effects do not occur in Weni brand lasers.

The main advantages of linear guides are : high stiffness, accuracy, extreme precision of movement, compactness, easy assembly and operation.

Professional refrigerator CW 3000-5200 is designed to cool the laser tube in Co2 Weni lasers, using distilled water in a closed circuit. The main task of the device is to lower the water temperature to the value appropriate for the machine.

It has a display and a controller to monitor the cooling process. By triggering the alarm and stopping the machine operation process, the cooler protects the laser from damage. It allows for full optimization of the machining process, maintains the correct operating temperature of the laser tube and makes the cutting or engraving uniform throughout the entire use process. A properly selected cooler extends the life and efficiency of the CO2 tube and the entire laser device.

Stainless connecting elements they are present in all Weni Solution lasers. which contributes to keeping the device clean and its correct operation. The basic properties of stainless steels used for the production of connecting elements (i.e. bolts, nuts, washers, etc.) include:

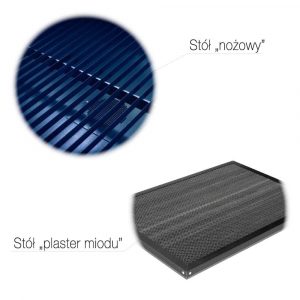

Two work tables: The knife and honeycomb are included in the standard equipment of Weni Co2 lasers. The knife table is used to cut large, rigid elements, while the honeycomb is ideal for processing small, flexible or materials that must remain on the table in a specific position after cutting.

The most important features:

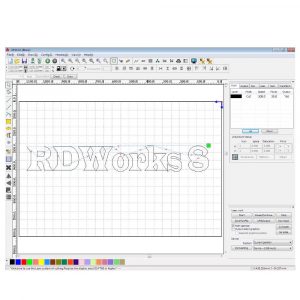

RDWorks software for Co2 lasers Weni is an advanced and intuitive solution that allows you to easily create even the most complex projects. The program works directly with the laser, so the transition from design to machine operation is very quick.

RDWorks together with the PL instruction, it is attached to each Weni laser. The software has a lifetime license and can be used interchangeably on many workplaces.

| Material | Thickness | W2 | W4 | W6 | W8 |

| Akrylic | 3mm | 35mm/s | 47mm/s | 62mm/s | 68mm/s |

| 5mm | 25mm/s | 31mm/s | 36mm/s | 40mm/s | |

| 8mm | 15mm/s | 19mm/s | 25mm/s | 34mm/s | |

| 10mm | 9mm/s | 15mm/s | 21mm/s | 29mm/s | |

| 15mm | 8mm/s | 12mm/s | 17mm/s | 19mm/s | |

| 20mm | 1.5mm/s | 2.4mm/s | 5mm/s | 9mm/s | |

| 30mm | - | - | 1.5mm/s | 3mm/s | |

| MDF | 3mm | 23mm/s | 25mm/s | 30mm/s | 33mm/s |

| 5mm | 15mm/s | 18mm/s | 21mm/s | 25mm/s | |

| 10mm | 7mm/s | 9mm/s | 12mm/s | 14mm/s | |

| 15mm | 3mm/s | 5mm/s | 7mm/s | 10mm/s | |

| 20mm | 1mm/s | 1.5mm/s | 2mm/s | 3mm/s | |

| Leather | jedna warstwa | 30mm/s | 40mm/s | 50mm/s | 60mm/s |

| Wood | 3mm | 25mm/s | 30mm/s | 35mm/s | 40mm/s |

| 5mm | 20mm/s | 25mm/s | 30mm/s | 35mm/s | |

| 10mm | 12mm/s | 15mm/s | 20mm/s | 25mm/s | |

| 15mm | 8mm/s | 11mm/s | 15mm/s | 18mm/s | |

| 20mm | 1mm/s | 2mm/s | 2.5mm/s | 3mm/s | |

| Textiles | jedna warstwa | 200mm/s | 300mm/s | 400mm/s | 500mm/s |

| Two-layer disc | 2mm | 40mm/s | 45mm/s | 55mm/s | 65mm/s |

| Paper | jedna warstwa | 200mm/s | 200mm/s | 200mm/s | 200mm/s |

| Rubber | 4mm | 35mm/s | 40mm/s | 45mm/s | 50mm/s |

| Material | Engraver | Cutting |

| Glass | YES | NO |

| Ceramics | YES | NO |

| Marble | YES | NO |

| Matte board | YES | YES |

| Wooden veneer | YES | YES |

| Fiberglass | YES | YES |

| Tile | YES | NO |

| Plastic(PMMA) | YES | YES |

| Cork | YES | YES |

| Corian | YES | YES |

| Cork | YES | YES |

| Cartboard | YES | YES |

| Plexiglass | YES | YES |

| Stainless steel | YES | YES |

| Carbon steel | YES | YES |

| Mosiądz | * | NO |

| Brass | YES | YES |

| Anodized aluminum | * | NO |

| Painted metals | YES | YES |

| Titanium | * | NO |

Attention! It is not possible to mount the W8 tube when choosing the size of the working area of 1300x900mm and 1000x600mm!