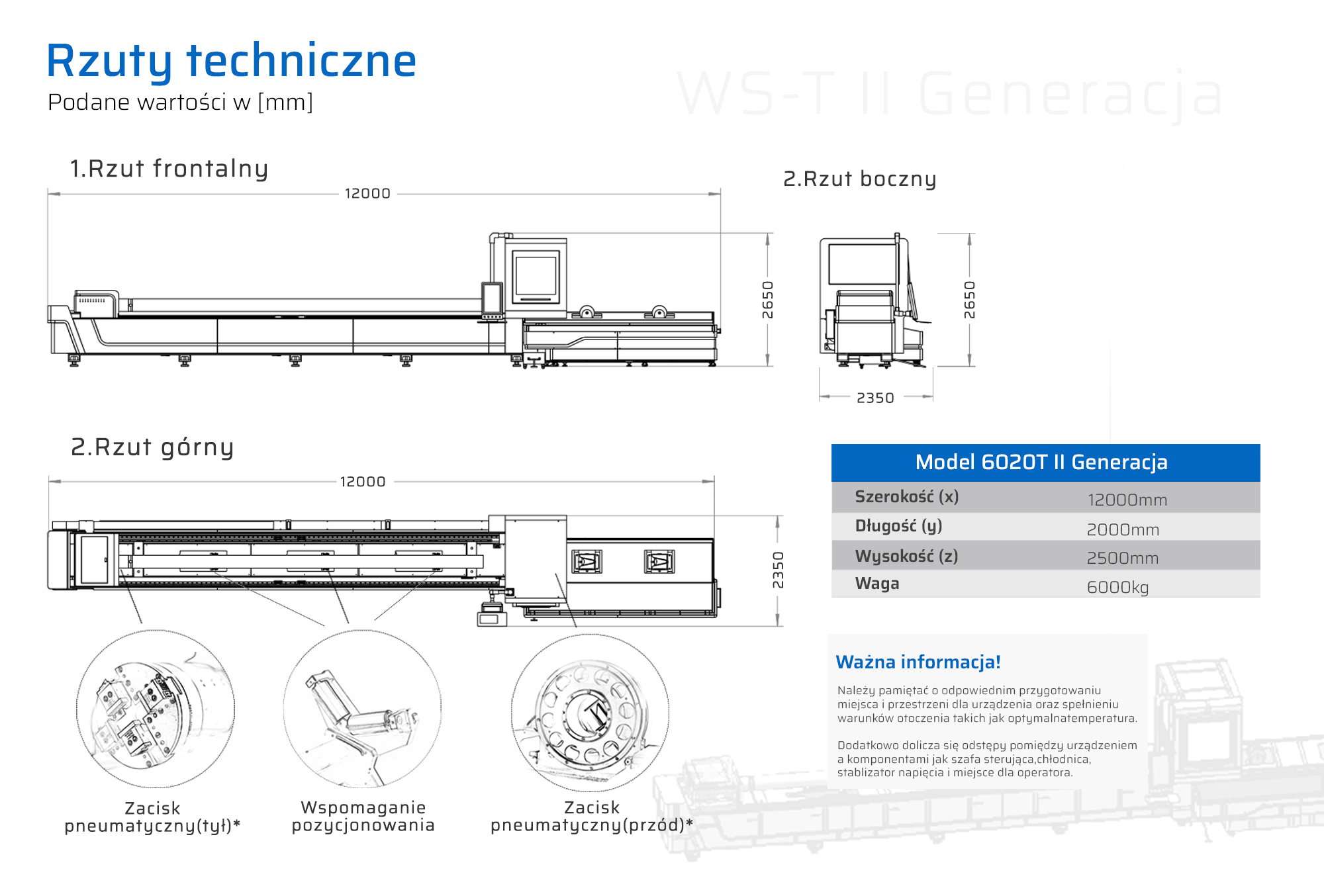

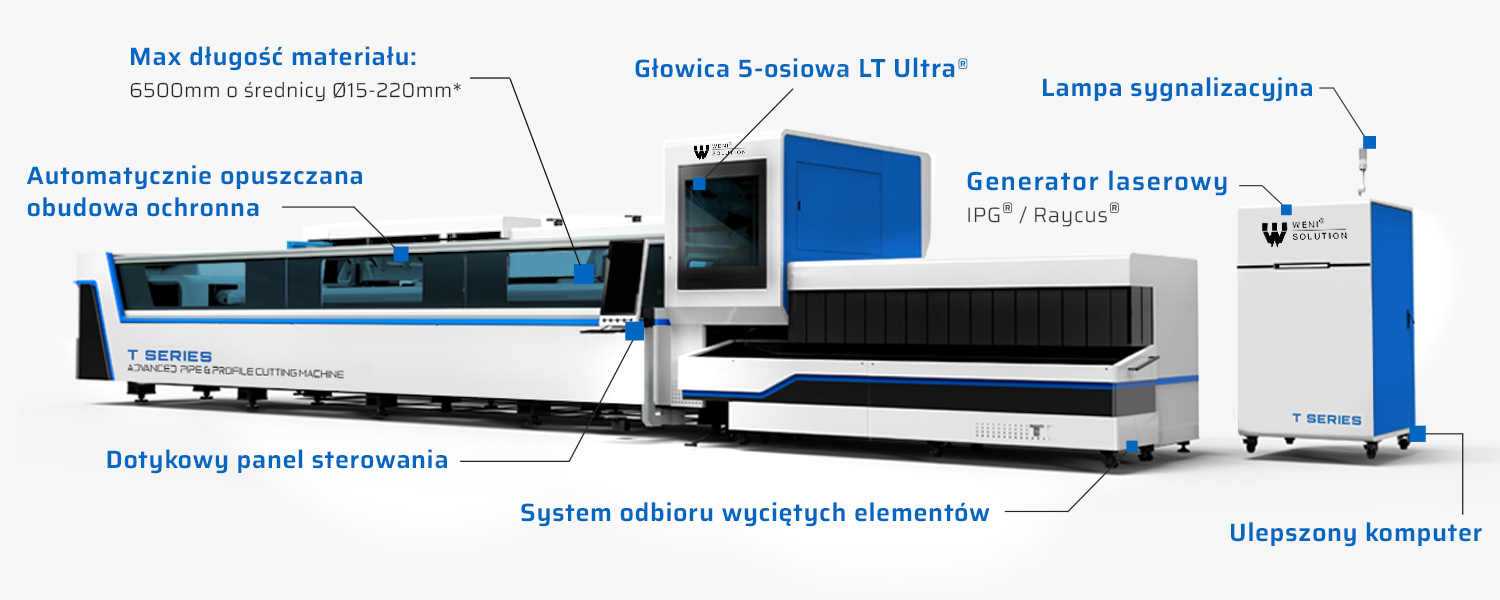

The second generation WS-T model is the most advanced device for cutting pipes and profiles in our offer of fiber lasers. The second version of the flagship series dedicated to processing spherical materials is undoubtedly the best in its class. The improved WS-T model is primarily a reinforced structure, even greater precision and speed of cutting, and an improved on-board computer. In addition, the device is equipped with a touchscreen, the ability to mount a 5-axis head, which allows for many more production possibilities, and the best components that make this device meet the expectations of even the most demanding customers.

See also similar models to the one being viewed:

Also check our lasers AVAILABLE

Automate the production process

Unlike the previous generation, we added the ability to expand the machine with an automatic loading system, which saves operators' time in the first place, speeds up the production process and makes the cutter a fully automated system for processing spherical objects. It is a system based on overhead cranes, motors and drive belts, which transfer the material to the clamps at high speed.Precision and repeatability of pneumatic clamps

In this version, we used reliable pneumatic chucks that take care of precision during rotation, while keeping the material intact throughout the machining process. The fabric is clamped with the sliding rear handle and the guiding front handle. In addition, we have introduced a material collection system after processing, which makes it easier to deliver ready-made items to the storage site.Servo drives support - positioning system

For even greater precision, we have introduced an intelligent positioning system that supports servo motors to keep the workpiece in the right position. The power, as well as the positioning angle, is adjusted on the fly during cutting. The system also ensures that the material does not shift or change angle, as well as imparting the proper speed and rotation of materials.The durability of the structure above all

Our priority when introducing the second generation of the WS-T model was to strengthen the cast-welded structure with an emphasis on strength and stability. The overall size of this device and its speed of movement mean that the best stiffening is needed so that the processed materials always maintain the set parameters. Casting with honeycomb structure with dislocation of 12-16mm carbon steel prevents stresses arising from high temperature machining. It also reduces vibrations produced by fast movements, resulting in much better precision.3D cutting - cut complex elements

LT Ultra 5-axis head® it is, above all, greater possibilities. The head movement is extended by two axes: A and B, which allows you to make angled cuts, and makes machining more accurate, faster and allows you to cut more complex shapes. All Weni fiber lasers are equipped with Auto Focus as standard. This feature is applicable to various focal lengths that are controlled by the laser control system. The focal point will be automatically adjusted during the cutting process in order to obtain the best cutting effect for different thicknesses of metal sheets. In practice, this means changing the thickness of the workpiece by the operator, without manually adjusting the focal length again.

The 5-axis head means, above all, greater possibilities. The movement of the head is extended by two axes: A and B, which allows you to make notches at an angle, and also make the machining more accurate, faster and allows you to cut more complex shapes.

The heads have been produced in Germany since 1995. The LT Ultra company is one of the most recognized manufacturers of optics, heads and UP devices in the world. A recognized brand guarantees our customers the quality and precision of one of the most important components used in our device.

The use of torque motors only reduces the mechanical displacement of the components, guaranteeing consistently high machining accuracy and the best cutting results over a long service life. The proven 3D collision protection function reliably protects against mechanical damage.

As an expert in energy chain systems, igus® has been supplying all components from a single source since 1964 - including cables. The technology and solutions developed and improved over the years by the German company igus® are unrivaled.

Contrary to the frequently offered spliceable cable options, igus® manufactures chainflex® cables based on the bundled principle. Motionplastic® technology is used in most professional devices on the market - we offer it as standard and use it in each of our devices.

Furthermore, igus® cables are covered by the manufacturer's lifetime warranty and are included in the price - with no hidden costs

MINAS A6B servo drives provide a much better positioning speed and meet the requirements of modern technology. It is one of the best solutions when precision is required.

The design of the MDDLNXXBE models with reduced weight and dimensions as well as increased shock resistance are the most compact servo drives on the market.

Main features:

• Max speed: 6500r / min

• 23-bit encoder - 8x higher resolution

• 5mbps communication speed

• Panaterm support • Built-in filters and customization functions

• 3.2kHz frequency in responsiveness

• Maximum acceleration: 350% faster

compared to the older series

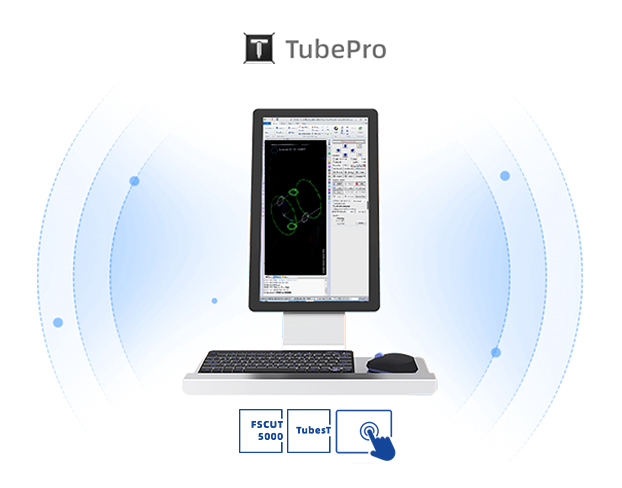

The nesting technology (Nested Based Manufacturing or NBM) significantly shortens and improves the production process, especially in the case of curved cuts.

Thanks to the possibility of positioning whole sheets of plates, it allows for better use of the raw material, i.e. reducing the amount of waste generated. Nesting enables optimal use of the material, and the cutting simulation function will allow for appropriate production planning / Production planning: Before the actual machining, the simulation function will determine the time needed to complete the task.

Wuhan Raycus Fiber Laser Technologies Co., Ltd. is a leader in the production of laser generators in the Asian market. Wuhan Raycus has an international team of specialists conducting development research, which allows the improvement and expansion of laser generators.

A great advantage of the company is the service and technical support department, and all repairs of devices take place directly at the customer's premises.

Raycus RFL series laser generators available from 500W to 12000W.

The TubePro laser cutting control system is a system software suite designed for spherical laser cutting. Includes laser cutting, common layout function and laser processing control. Most of its functions are cutting parameter settings, custom editing, simulation and control of the cutting process.

The TubePro software provided with the device enables:

Rail guides in our lasers are provided by three top manufacturers: PMI Linear Motion, HIWIN® and THK Global. They ensure high positioning accuracy, high repeatability and durability.

Linear guides ensure smooth movement of the trolley thanks to the use of rolling elements - balls or rollers. The difference between static and dynamic rolling friction is very small, so that the starting force is only slightly greater than the force supporting the movement. Therefore, stick-slip effects in Weni brand lasers do not occur.

The advanced cooling unit CW-6200 is a device designed to ensure the optimal operating temperature of both the generator and the laser head. Advanced automatics used in our units allow precise control of the coolant temperature.

The built-in alarm system informs the user about exceeding the permissible operating temperatures and about disturbances in the cooling liquid flow.

A modernized automatic lubrication system that complements the lubrication of the gears and bolts.

This system takes care of the regular supply of lubricants and extends it

service life of the machine. Contrary to the previous generation and the competition, the system takes care not only of guides but also of all components that require it. The system itself calculates the time and the amount of lubricant that is required.

The structure of the machine bed is welded and cast with an emphasis on strength. Then, the whole is subjected to high-temperature annealing treatment, the purpose of which is to remove internal stresses from the machine bed, thanks to which the machine remains stable during use and unchanged for up to 10 years.

Casting with honeycomb structure with dislocation of 12-16mm carbon steel prevents stresses arising from high temperature machining. I also reduce the vibration produced by fast movements, which translates into much better precision.