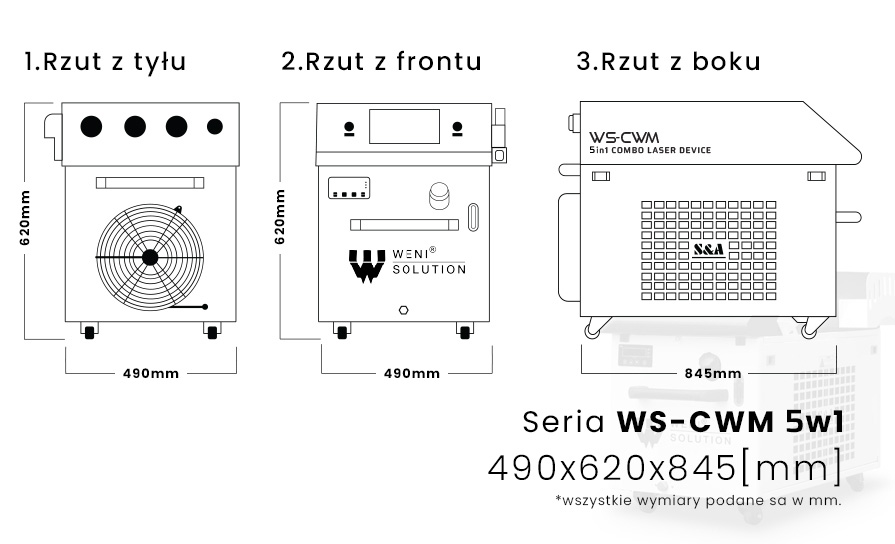

The WS-CWM laser welder is a 5-in-1 device that combines precision welding function with spot welding, weld cleaning, cutting and cleaning capabilities.

Fast and easy welding of even thin materials - Weni Solution laser welders are all about easy creation of professional welds, low cost of operating the device, and the ability to join together materials with different properties, such as stainless steel and aluminum.

Spot welding - allows to obtain extremely durable joints, characterized by high mechanical and structural strength. Thanks to a properly conducted welding process, the connected components guarantee stability even under operating conditions.

Weld cleaning - with proper cleaning of the weld, it is possible to achieve high-quality joints that meet the highest standards required in many fields of industry and manufacturing. This function includes removing contaminants and excess material from the weld area for optimal weld quality.

Laser cleaning - by making maximum use of the laser generator's capabilities, you can switch the device to cleaning mode and effectively remove contaminants from the material before welding or from a freshly made weld. Laser ablation is the most environmentally friendly solution that quickly and without the use of chemicals removes dirt such as rust, paint, oil and others.

Cutting metal (fiber torch function) - properly adjusted mode changes the parameters of the beam and allows you to cut material up to 4 mm thick.

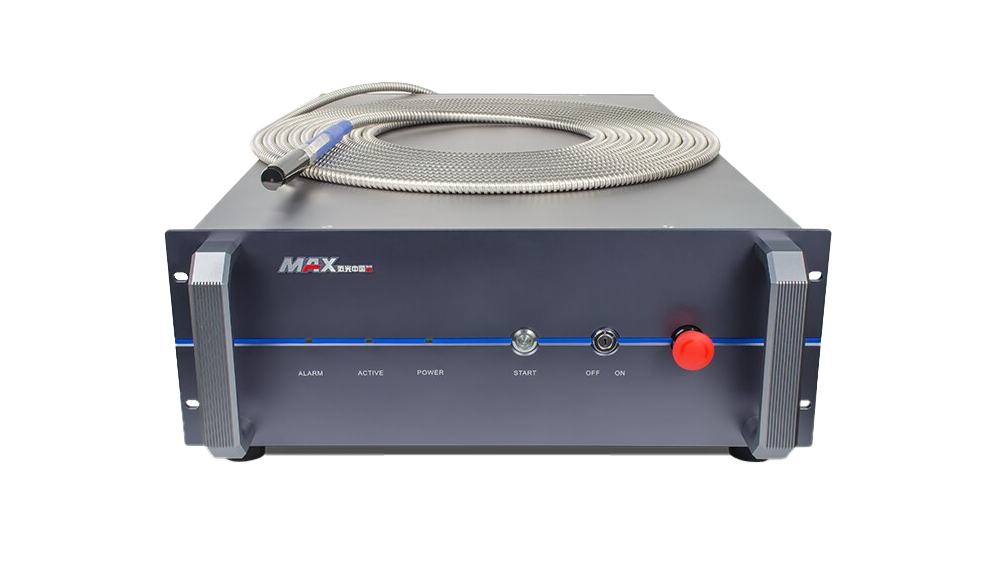

The device comes in 4 power variants: 1000W, 1500W, 2000W and 3000W.

See also other Weni Solution brand devices:

Also check out our devices AVAILABLE AT HAND or schedule a personalized, free demonstration in the Showroom!

Laser welding - joining materials has never been so easy!

The device is designed to make its operation as simple as possible for users, so creating welds does not require special operator training. The ability to weld with a handy head that operates in 360 degrees is undoubtedly one of the biggest advantages of this model. The WS-CWM welder can perfectly cope with the production of parts made of thin metal sheets. In addition, laser technology allows you to join different materials together, which is virtually impossible with traditional welding methods. An automatic wire feeder is also an integral part of the machine . This supports the operator's work - it helps guide the movement that creates the weld. The feeder has adjustable parameters, such as the delay time (delay), for example. It also has many other functions, including: Rollback (reversing the wire and winding it on the spool), or Push-Pull (feeding the wire properly and pushing back the welder's hand). Also included is a set of nozzles that can be quickly replaced and thus give a different shape to the weld and reach hard-to-reach areas such as curves or angles. The device does not require the use of electrodes, and thanks to the small laser beam, it is possible to weld with minimal spacing. Controlling the laser power, beam width, frequency and other parameters, the workpiece is melted, creating a perfect quality weld, as confirmed by the tests carried out and the Welding Quality Control Institute certificate.Many functions in one device!

Given its large production capacity and wide range of applications, the WS-CWM model is competitive with traditional welding machines at a very attractive price as well. It is a comprehensive solution that will improve the work of any production facility, as it combines the functions of a welding machine, cleaning laser and fiber optic cutter.Advantages of Weni Solution WS-CWM laser welding machine

- High quality, repeatability and strength of welds that do not require further processing,

- Easier to create aesthetically pleasing, long joints in one motion,

- Low operating costs and maintenance of the device,

- Intuitive operation and high process cleanliness,- High welding speed While maintaining quality,

- The ability to Work in longer intervals,

- Relatively Low power consumption,

- Handy head Allows 360-degree maneuverability,

- Ability to clean and cut workpiece materials,- The kit includes an automatic wire feeder and a set of nozzles, accessories and glasses.

Comparison of laser and traditional welding:

| Welding type | Laser welding | Argon arc welding |

|---|---|---|

| Welding method | Spot or continuous welding | Spot welding |

| Possible materials | Stainless steel, carbon steel, galvanized sheets, aluminum, etc. | Stainless steel, carbon steel, galvanized sheets |

| Minimum thickness | 0.5-4 | 1-12mm |

| Material deformation | Small | Large |

| Welding speed | 0-8m/min | 0-1m/min |

| Post-weld processing | Minimum / none | Required |

| Service level | Easy | Difficult |

| Safety and environmental protection | Relatively safe and environmentally friendly | Not |

| Cost of service | General worker (can be hired after simple training) | Professional welder |

| Consumable parts | Lens, nozzles | Electrodes, Porcelain nozzles |

| Gas | Argon/Azot | Argon |

Plus!

Comprehensive training and online support with a two-year warranty included. With the option to extend the warranty to up to 5 years!

The power of the laser generator affects the speed of melting and the speed of weld formation. By generating more energy faster, the higher-powered source makes it much easier to work with difficult metals. The higher power allows welding thicker materials by creating more extensive and stronger welds. It is recommended to use more power for the thickness of >4mm.

To cut high-reflectivity materials such as copper, brass, gold, and silver, we recommend choosing an IPG laser generator. In the case of MAX PHOTONICS and RAYCUS, there is a high risk of generator failure/damage.

The head installed in the WS-CWM series laser welder is part of an advanced water-cooled kit. This head is distinguished by the fact that, thanks to an interchangeable sleeve, the tip can be swapped with a nozzle for cleaning or welding. Thanks to the pull-out drawer, adjusting the right lens for the selected mode is much easier. The head also has a handle for connecting wire from an automatic feeder.

Several different types of laser welder nozzles are available, which affect the precision and better access to the gap between materials and help achieve the right shape of the weld. Replacing the nozzle is simple, fast and intuitive.

It is necessary to choose the right nozzle shape for a particular type of weld, such as external or internal, and for the thickness of the material to be welded. Moreover, by using a special cutting tip, the device can be used for straight cutting. The fiber optic cable to the head is 10 m long.

Weni Solution feeders are designed to combine easy operation and control of the machine along with excellent wire feeding. The use of a feeder is useful especially with thicker materials, as the wire fills the gap between the materials to be joined. The width of the wire handled is within the range: 0.8 mm - 1.6 mm. The roll that can be used should be max. 5-7 kg in weight. The feeder also has casters for greater mobility.

The feeder has features such as:

- Push-Pull functions, which feeds the wire and guides the welder's hand at the same time

- Possibility of manual wire tensioning (useful when putting on a new roll)

- Rollback function (reversing the wire and winding it on the spool)

- Other functions, such as wire feed speed and Delay time

An undoubted improvement for the operator is the introduction of an application in the device, which is used to change parameters in real time, without the need to approach the control panel. Special customization of RUIDA® controllers by Bluetooth® communication allowed us to design an application(Android/iOS) that is intuitive and speeds up the welder's working time significantly. In the application you will find a function for changing parameters such as frequency, but also a library of previously saved parameters.