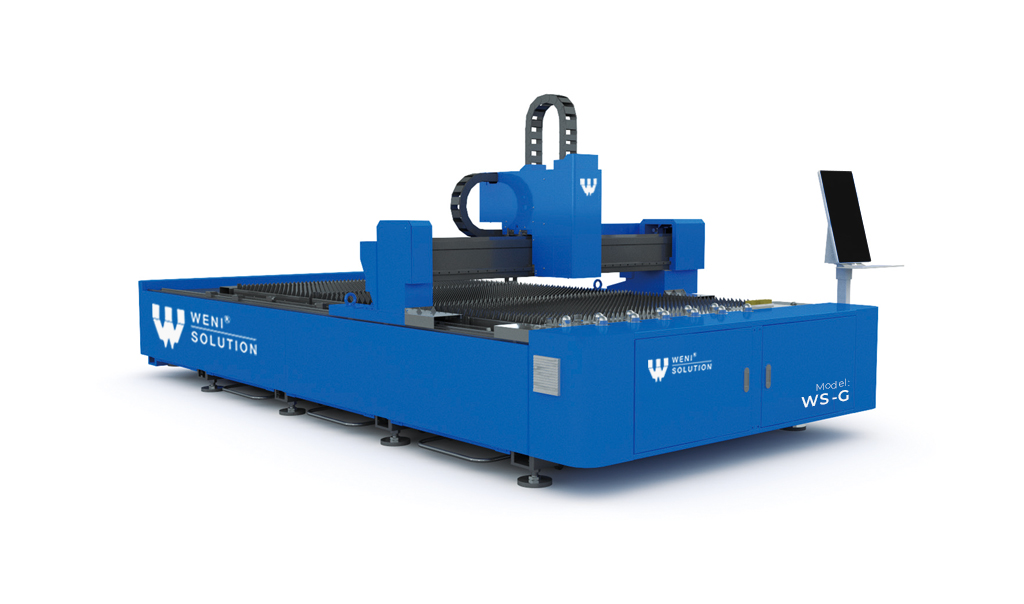

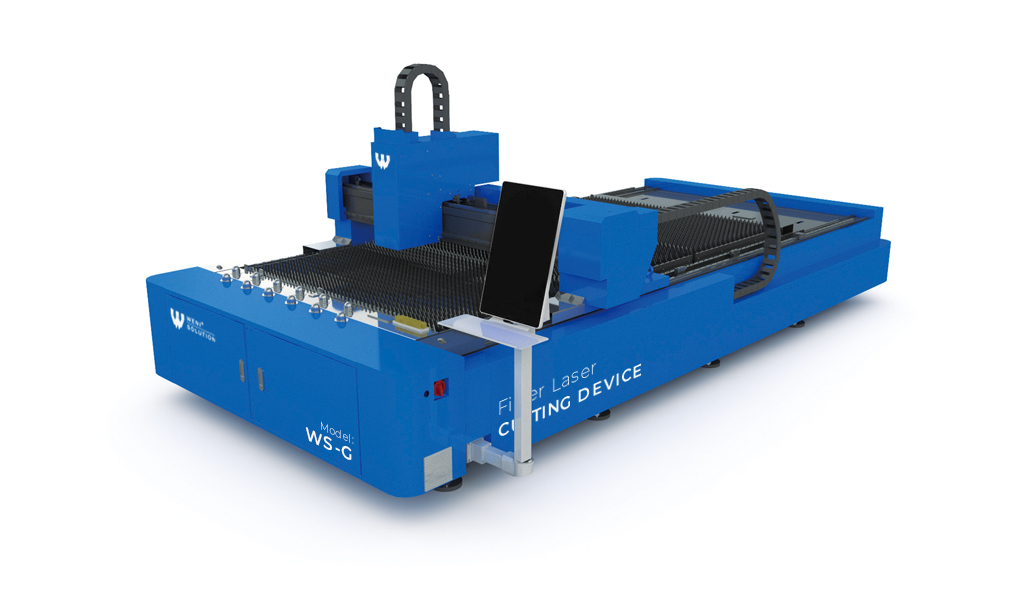

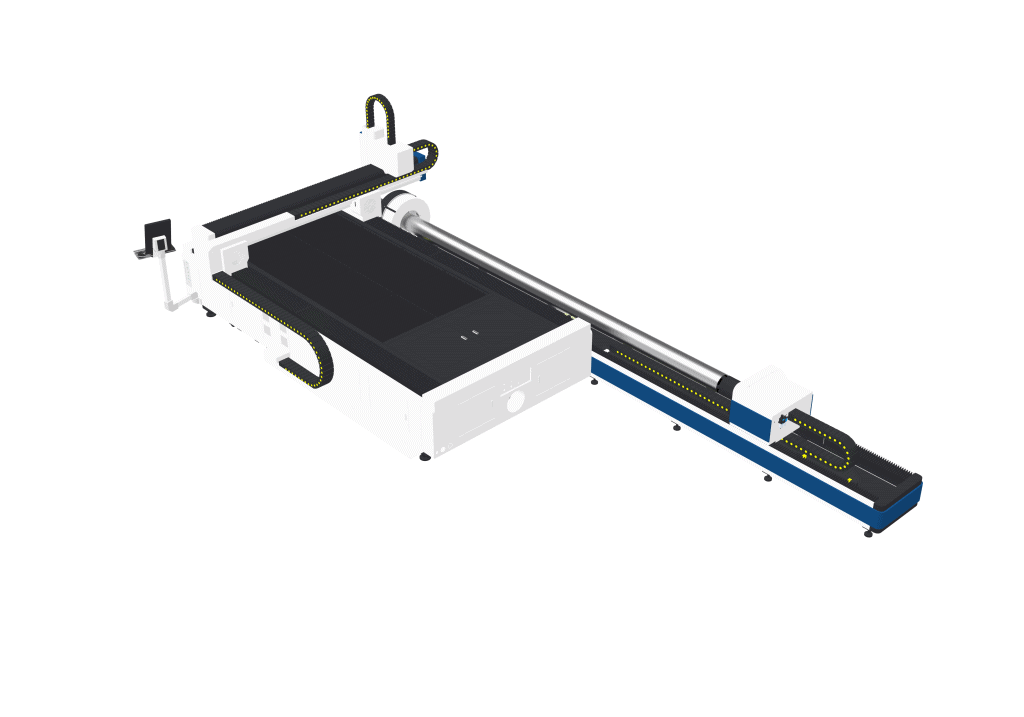

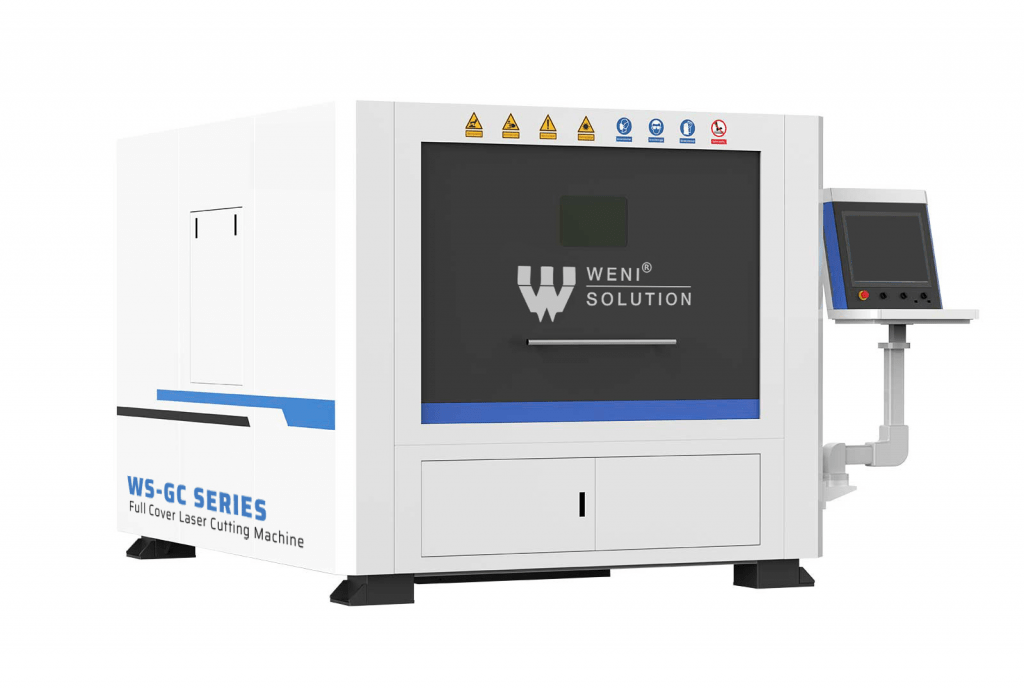

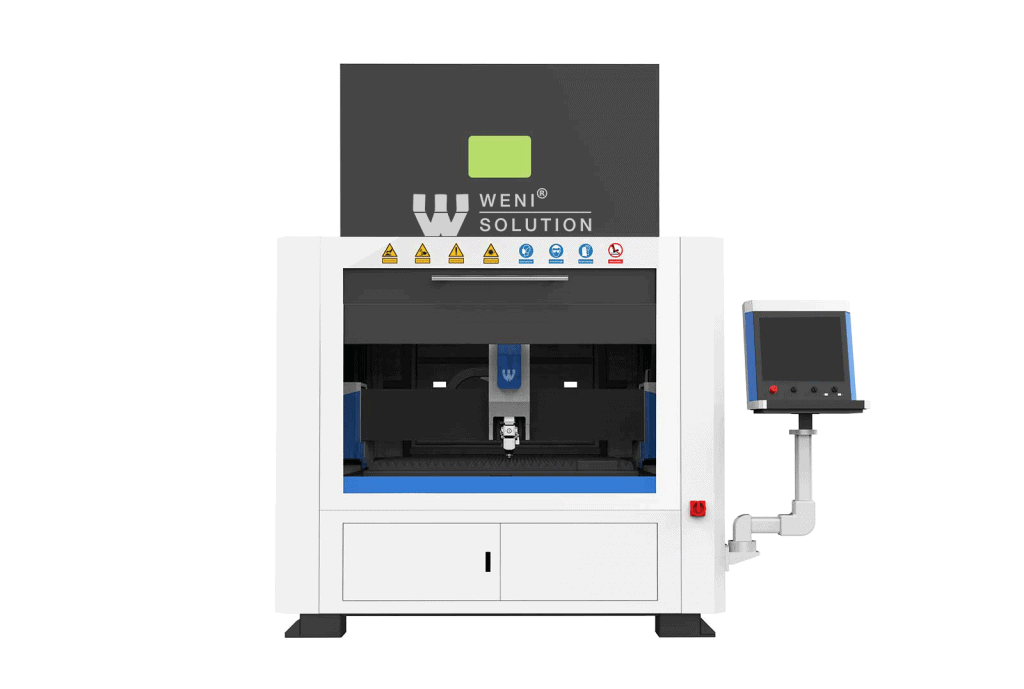

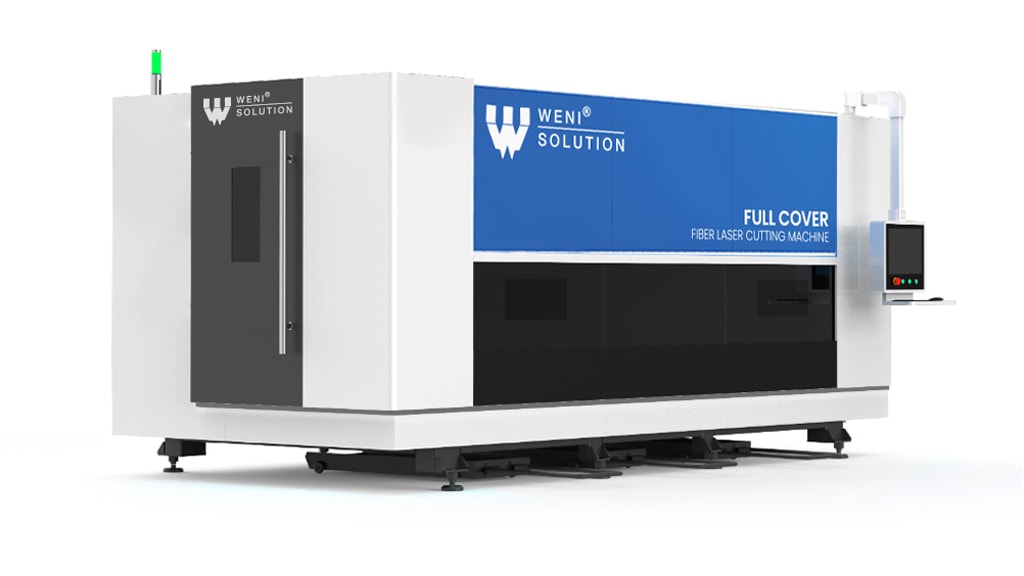

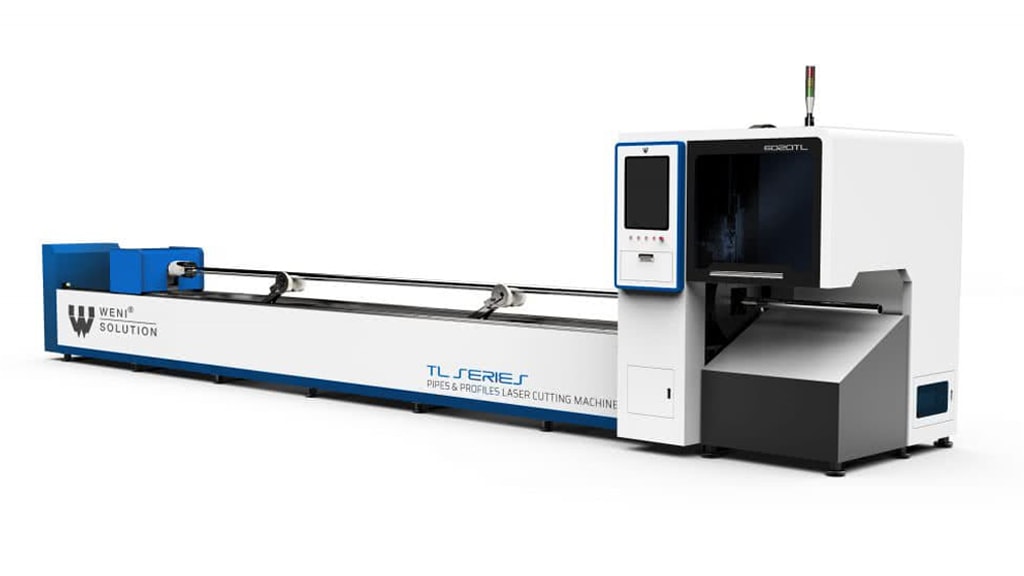

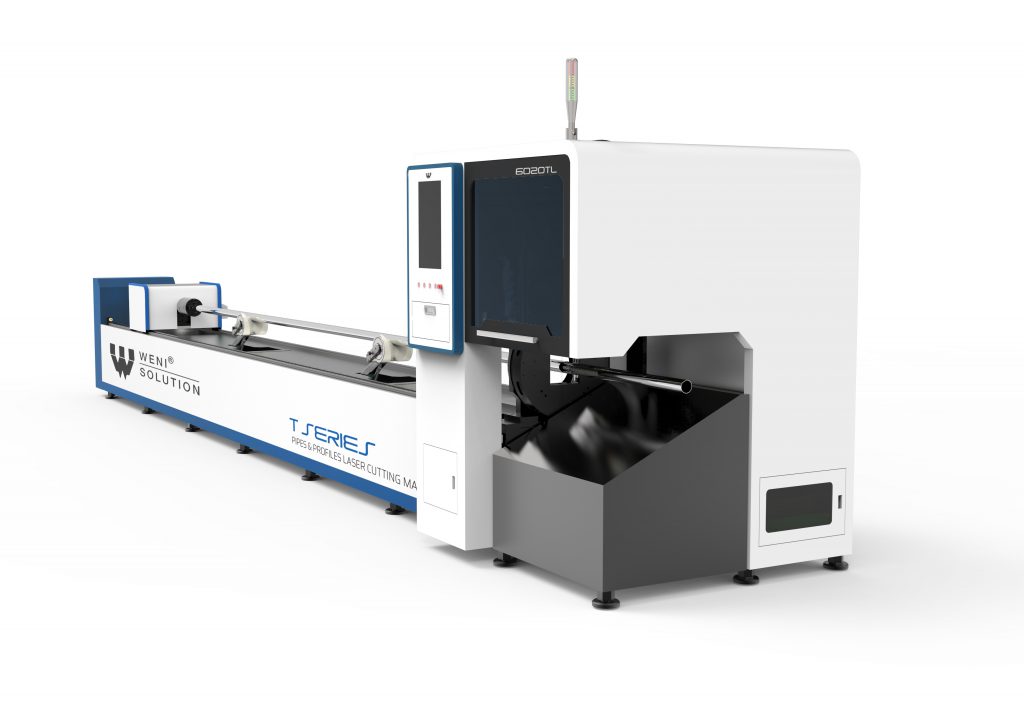

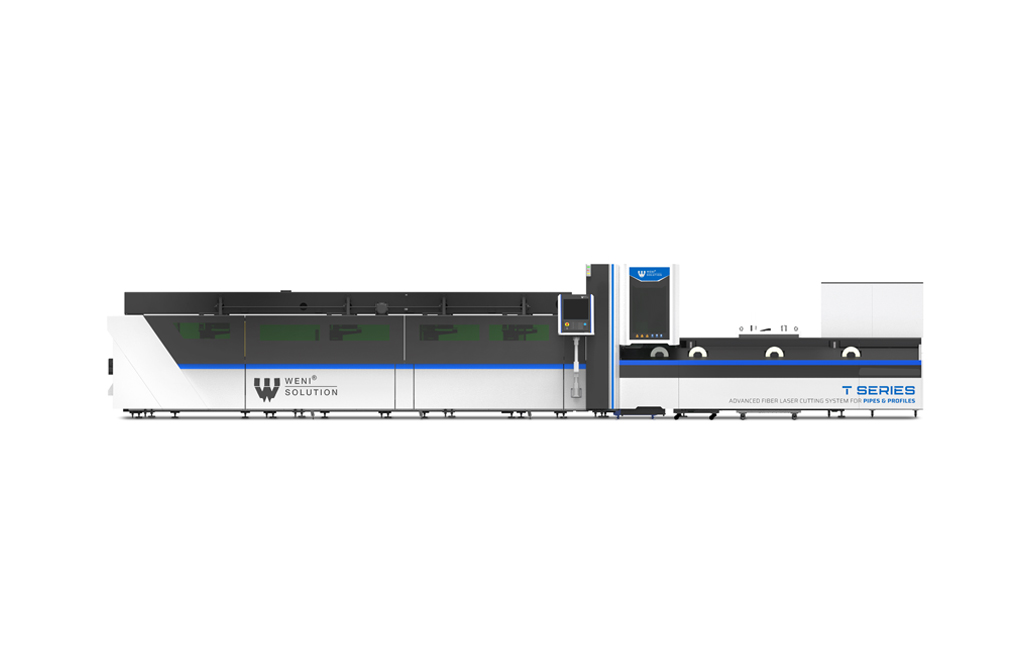

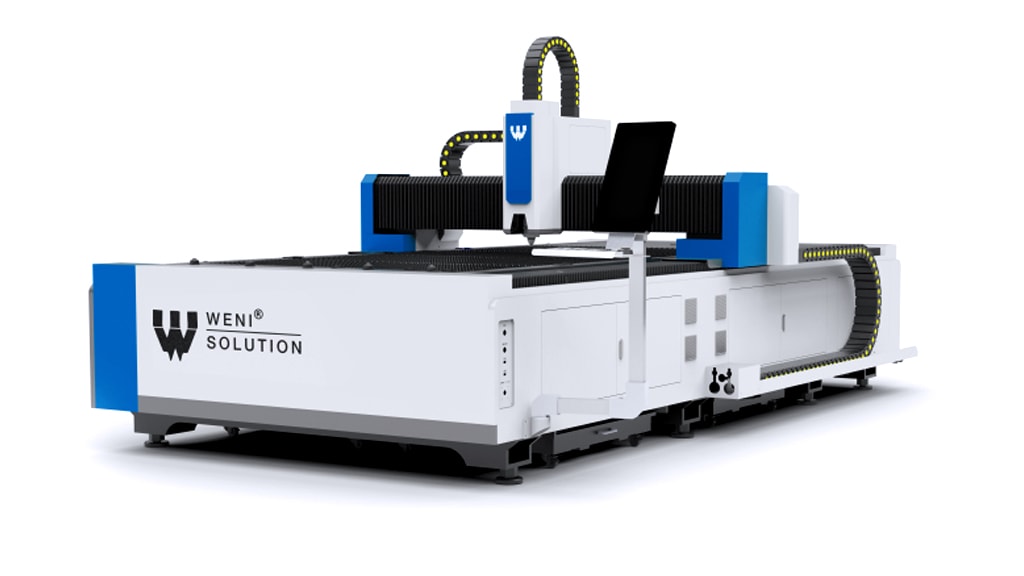

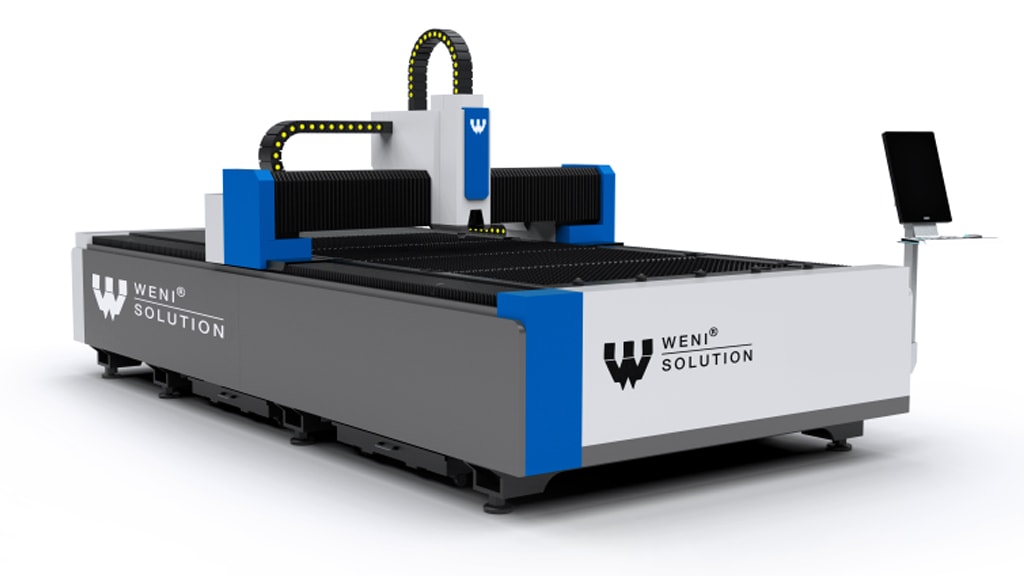

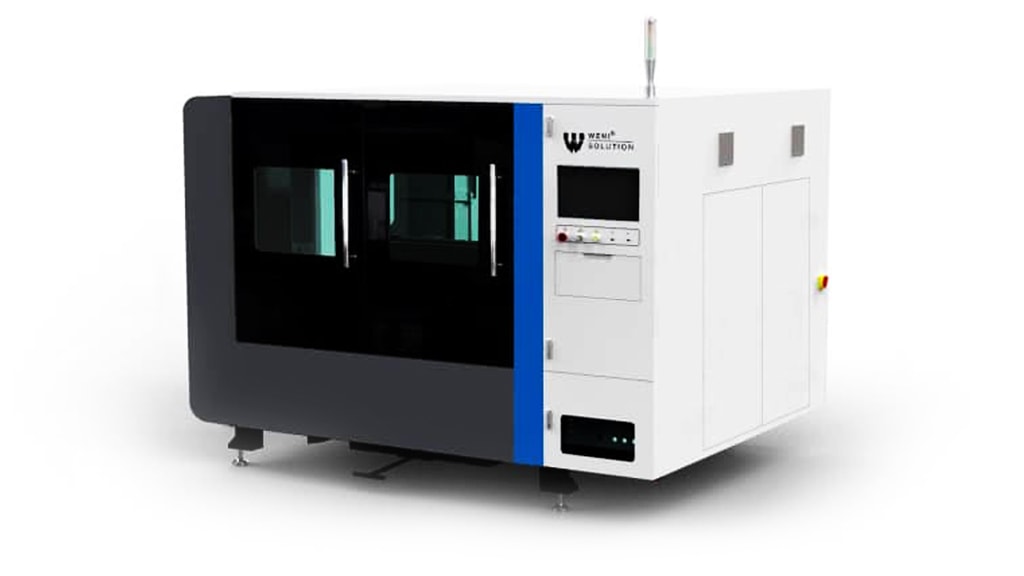

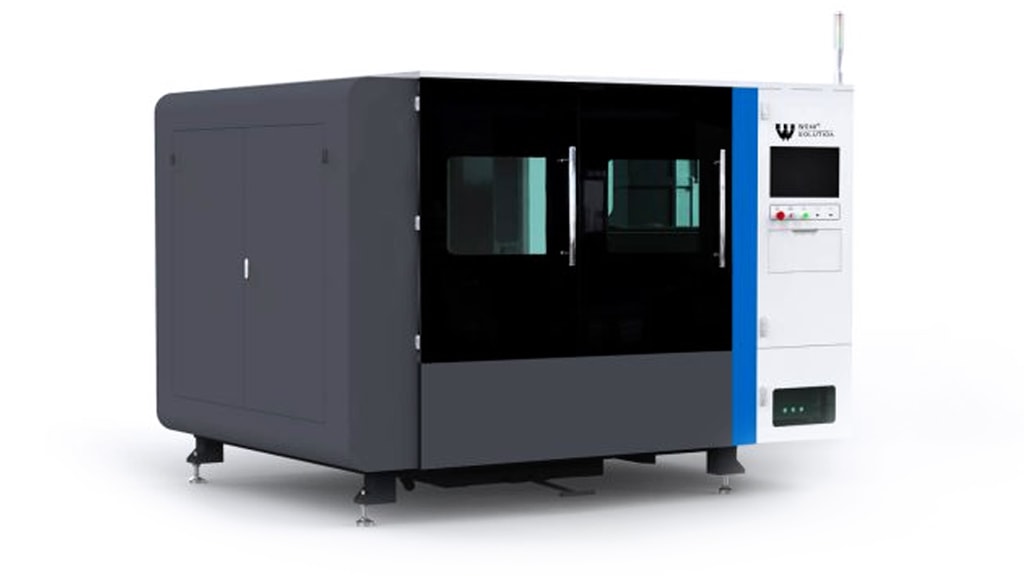

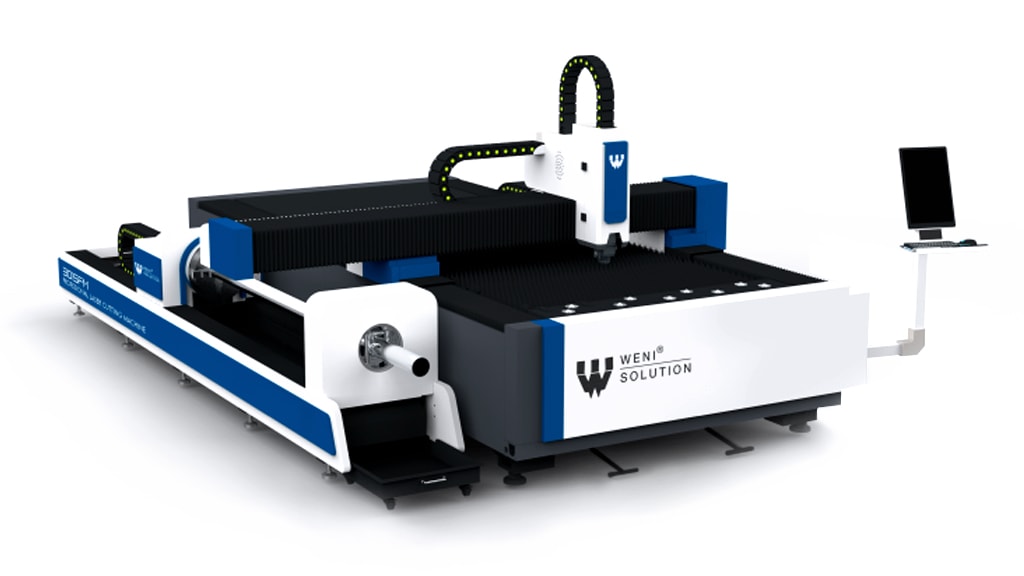

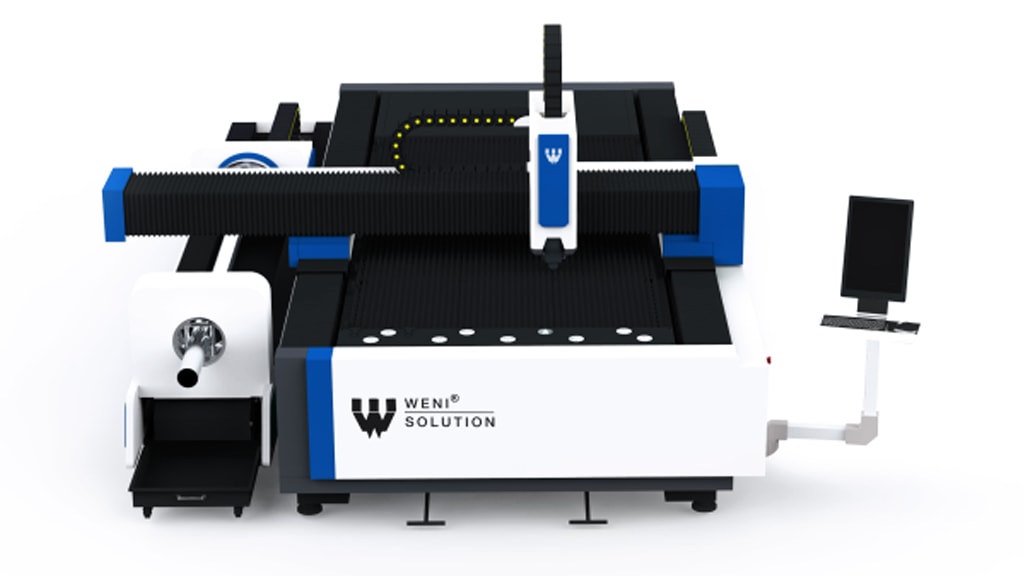

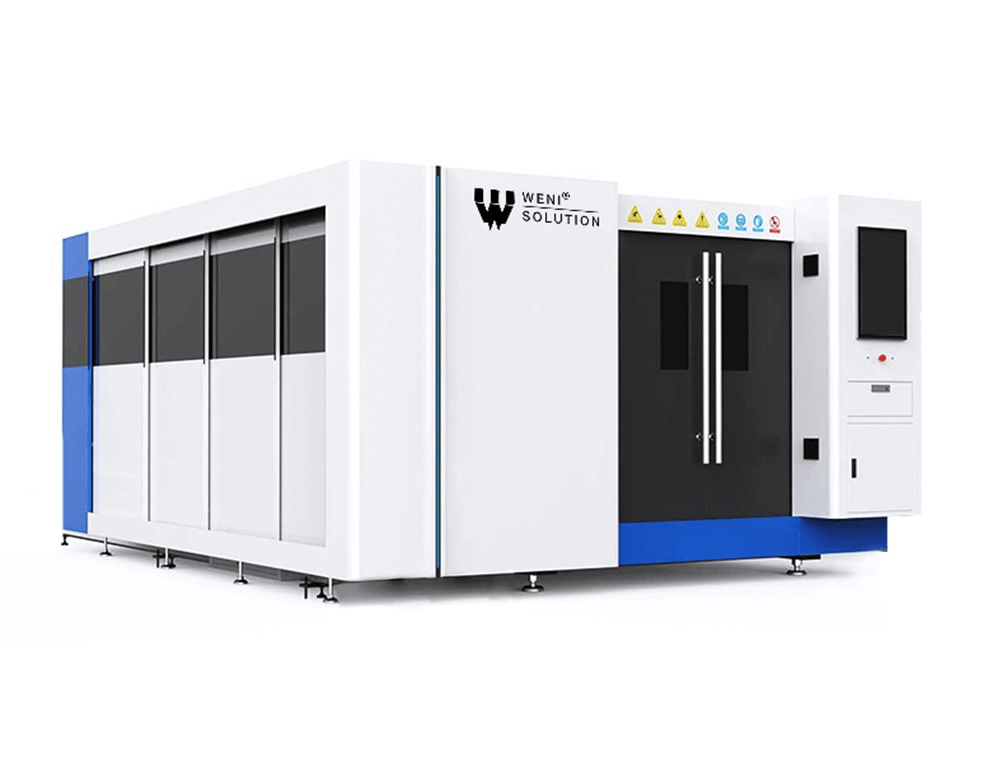

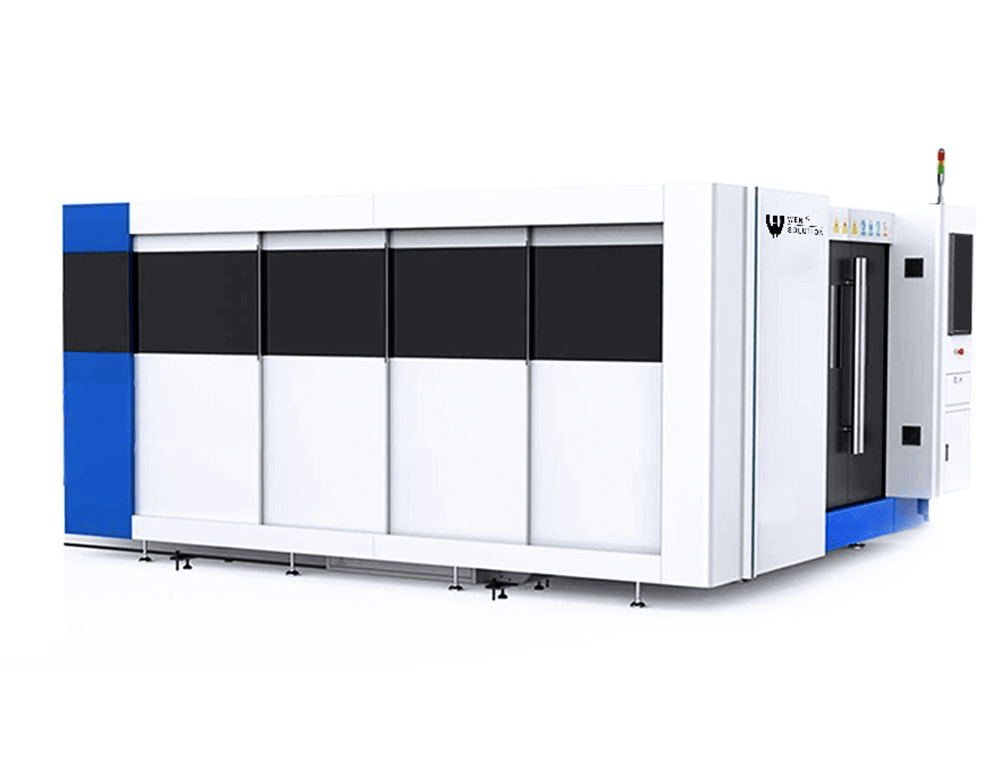

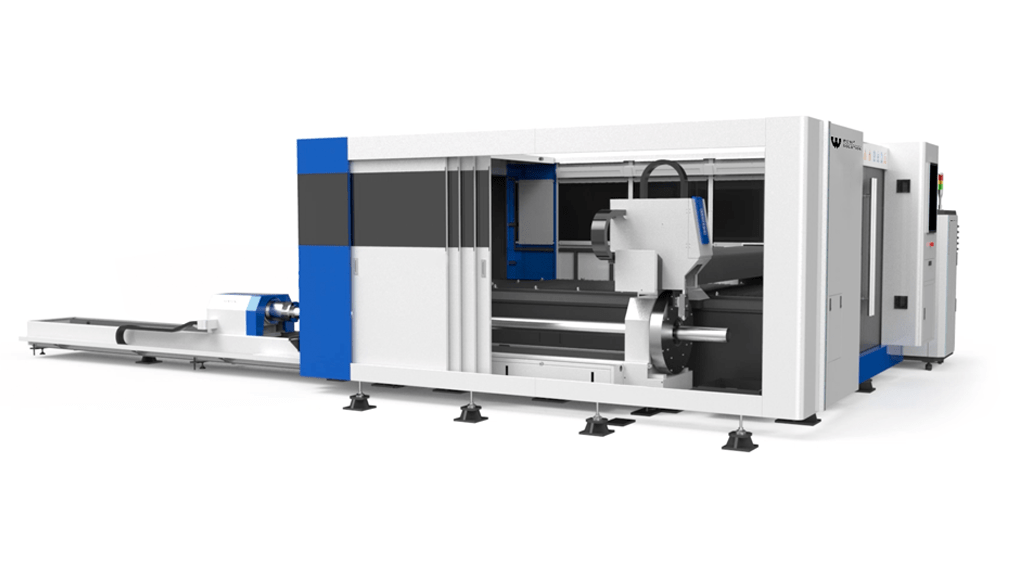

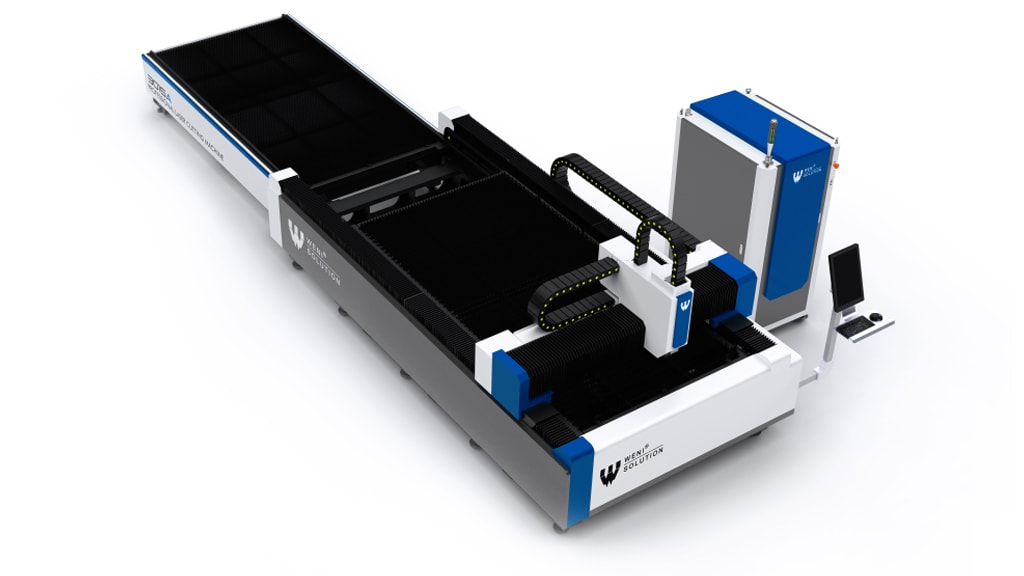

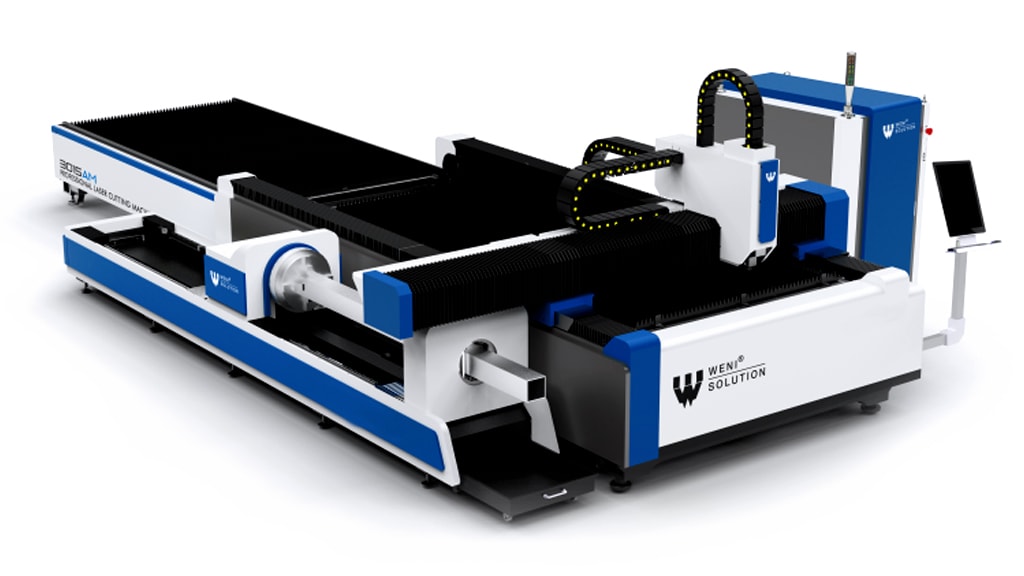

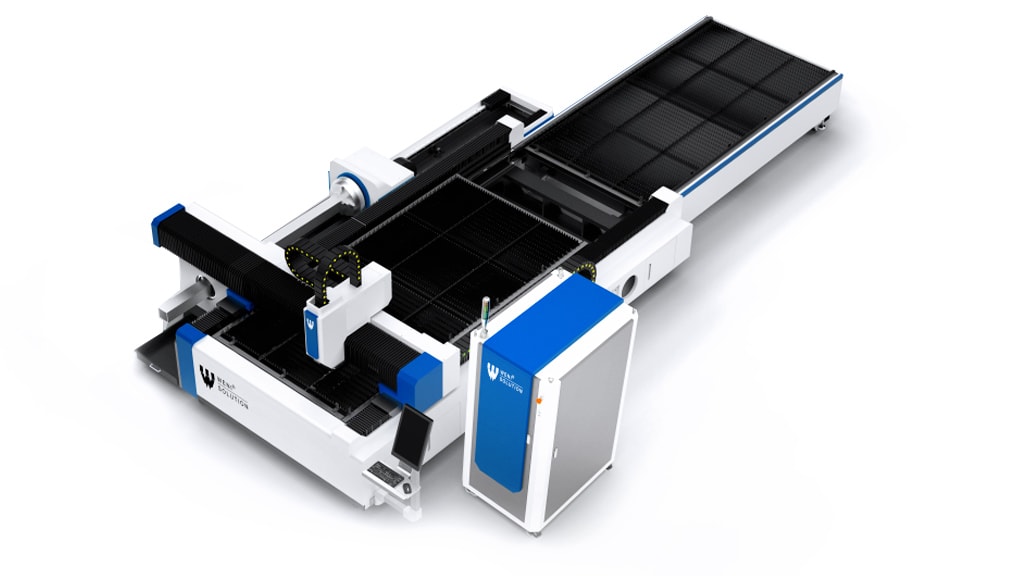

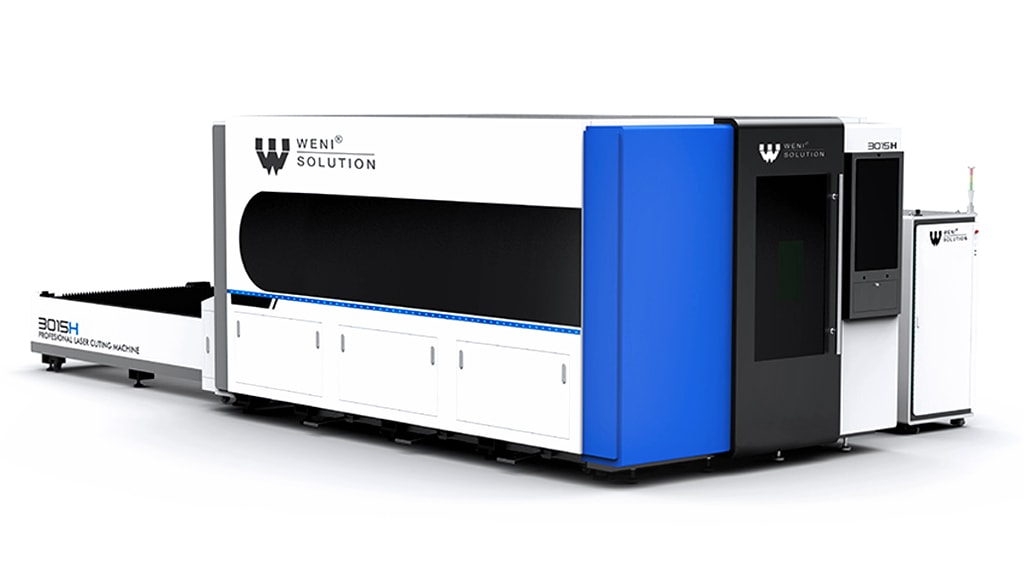

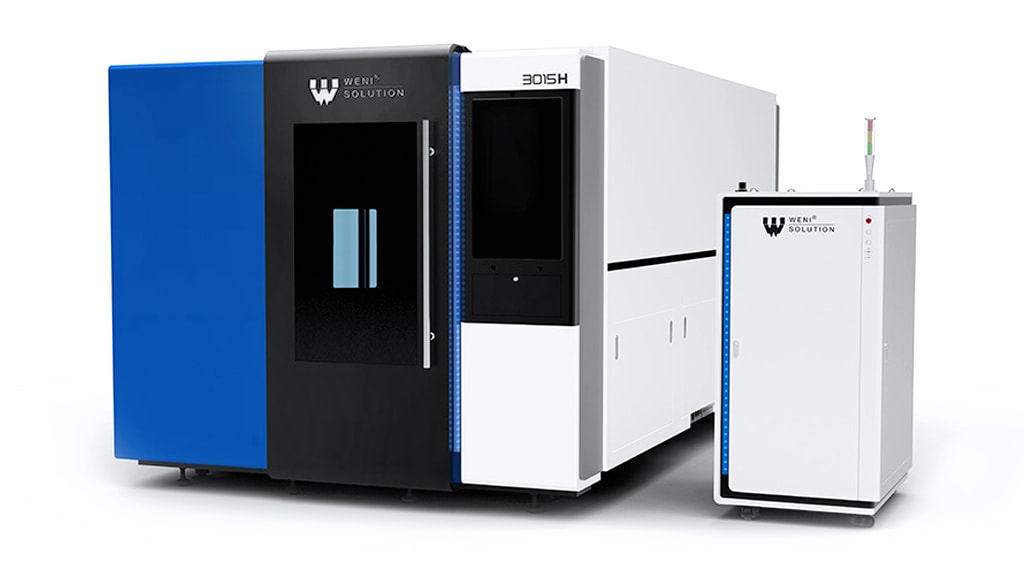

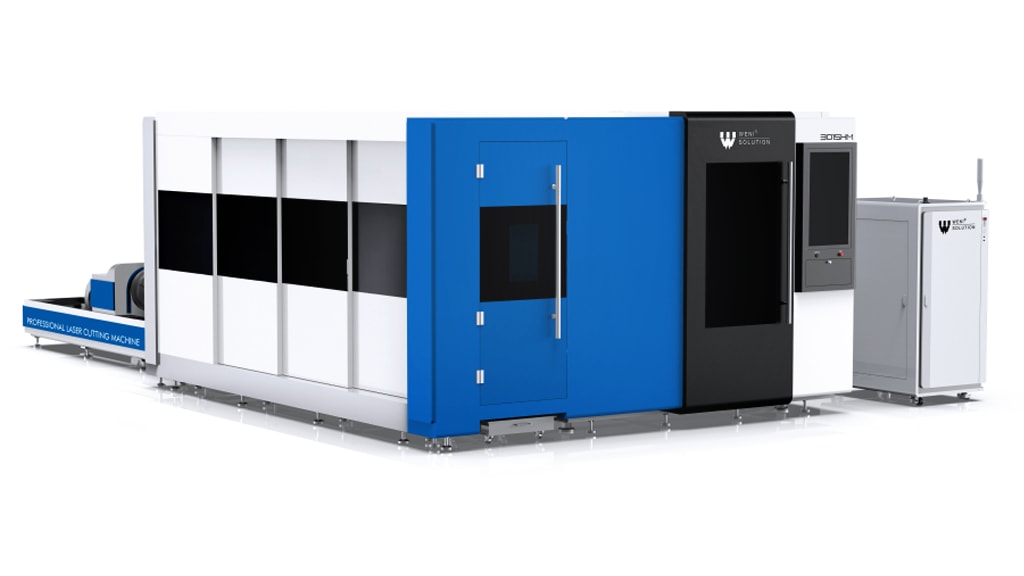

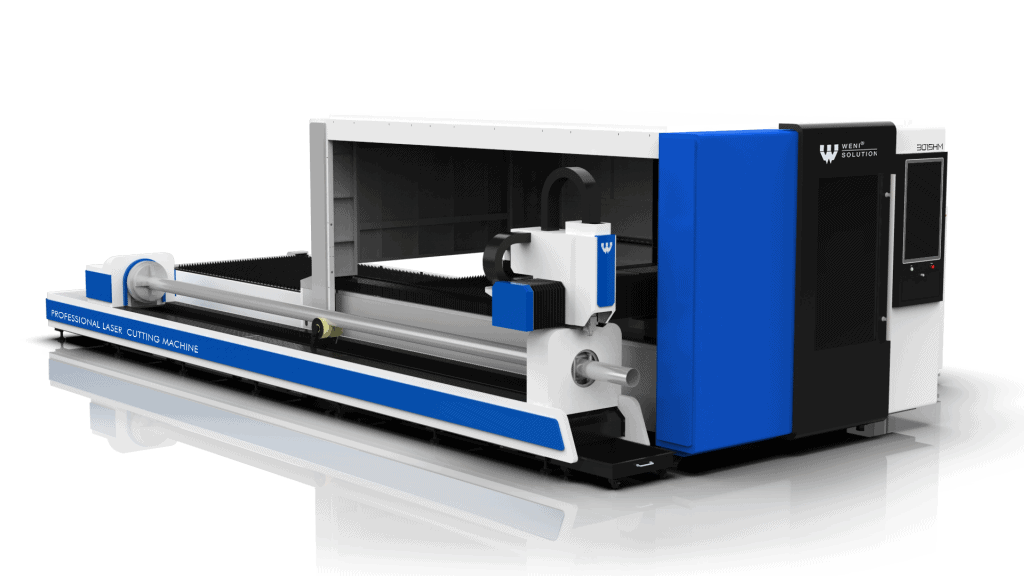

Efficient and innovative fiber lasers for mass, large-format and retail production. Raycus and IPG sources with nominal power from 500-12000 W. All lasers have autofocus, CypCut software and a nesting system. The voltage stabilizer allows for constant and even mains voltage without disturbances. We use components from reputable companies HIWIN, PMI, AirTAC, Shneider, Panasonic, Omron, Raycus, IPG. Optionally, lasers can be equipped with an automatic loading system and an extension for cutting pipes and profiles (open and closed).

€37.335,39

€58.418,28

€65.383,64

€54.682,07

€82.436,76

€58.685,15

€82.436,76