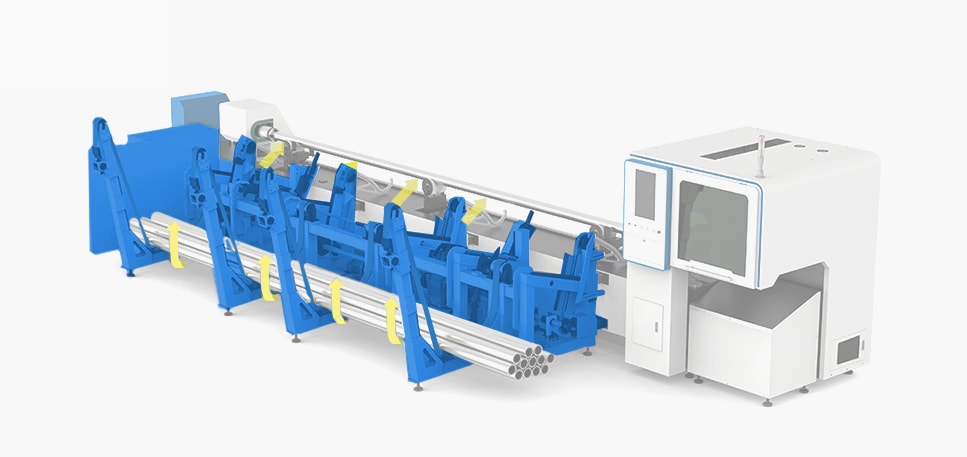

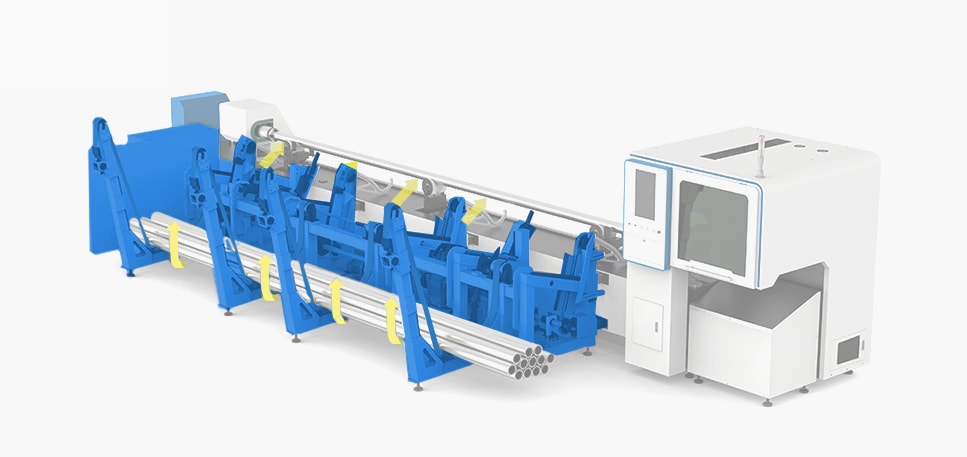

WS-TL BASIC is the latest version of lightweight laser cutters built for processing pipes and profiles up to 6000mm, with power from 1000W. This series uses a structure made of high-quality metal alloys and subjected to long-lasting and special treatment. The construction of the device allows for loading up to 300 kg. The use of the autofocus function allows for faster work, without the need to set the focal length manually. The automatic focus adjustment allows you to set the focal length for perforation and the focal length for cutting separately.

See also similar models to the one being viewed:

Also check our lasers AVAILABLE

The choice of the model depends on the client's expectations, planned production, prepared budget and many other factors. The models differ in the purpose, size and type of the work table, the possibility of cutting profiles, parameters, etc.

In the case of low-volume productions, small elements and for the company's production needs, it is best to choose the table size for the most commonly cut sheets, usually these are smaller sizes. In a situation where the manufacturing company accepts orders from the outside, it is recommended to choose a larger table, in the case of a project to cut a large element from one sheet.

Only one unit size is available for this model.

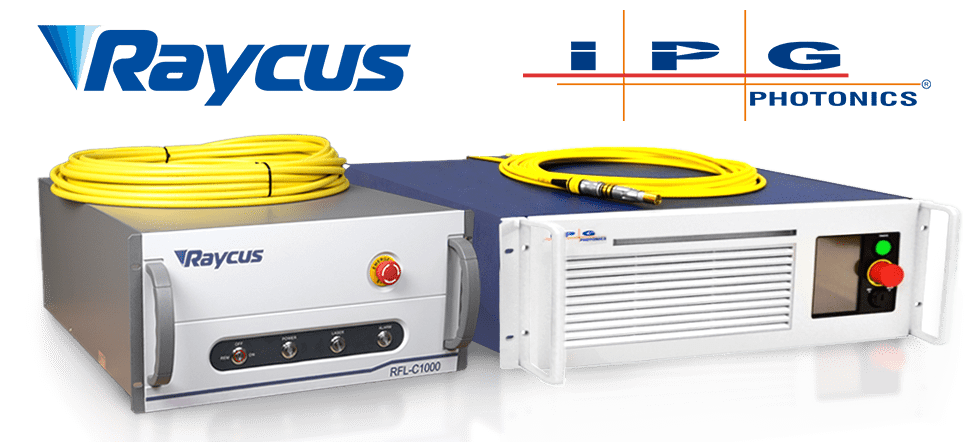

To cut high-reflectivity materials such as copper, brass, gold, and silver, we recommend choosing an IPG laser generator. In the case of MAX PHOTONICS and RAYCUS, there is a high risk of generator failure/damage.

Regardless of the choice of IPG / Raycus, our technicians recommend choosing a source with a power reserve (20-30%). The higher power of the laser generator proportionally improves the quality and economy of work.

What exactly do we get thanks to the higher power of the laser source?

Choosing an appropriately strong generator causes that:

- cutting is faster,

-we can cut thicker material,

-the entire cutting process uses less gas,

- edge quality is improved,

- the emission of gases and dust is reduced.

Note: For cutting highly reflective materials such as copper, brass, gold and silver, we recommend choosing an IPG laser generator ( with MAX PHOTONICS and RAYCUS, there is a high risk of failure / damage to the above-mentioned generators).

To cut high-reflectivity materials such as copper, brass, gold, and silver, we recommend choosing an IPG laser generator. In the case of MAX PHOTONICS and RAYCUS, there is a high risk of generator failure/damage.

It is especially recommended because increases the precision of control gas pressure and much reduces service time.

Electronic control of the first (oxygen) line is offered as standard with our fiber devices.

Each fiber device of our brand has two gas lines as standard: the first electronically controlled, the second manually controlled (with the possibility of changing to automatic). Cutting small parts or holes without automatic control wastes large amounts of steel and gas, and also makes it difficult to maintain edge quality.

To cut high-reflectivity materials such as copper, brass, gold, and silver, we recommend choosing an IPG laser generator. In the case of MAX PHOTONICS and RAYCUS, there is a high risk of generator failure/damage.

We recommend this option to everyone working with laser technology.

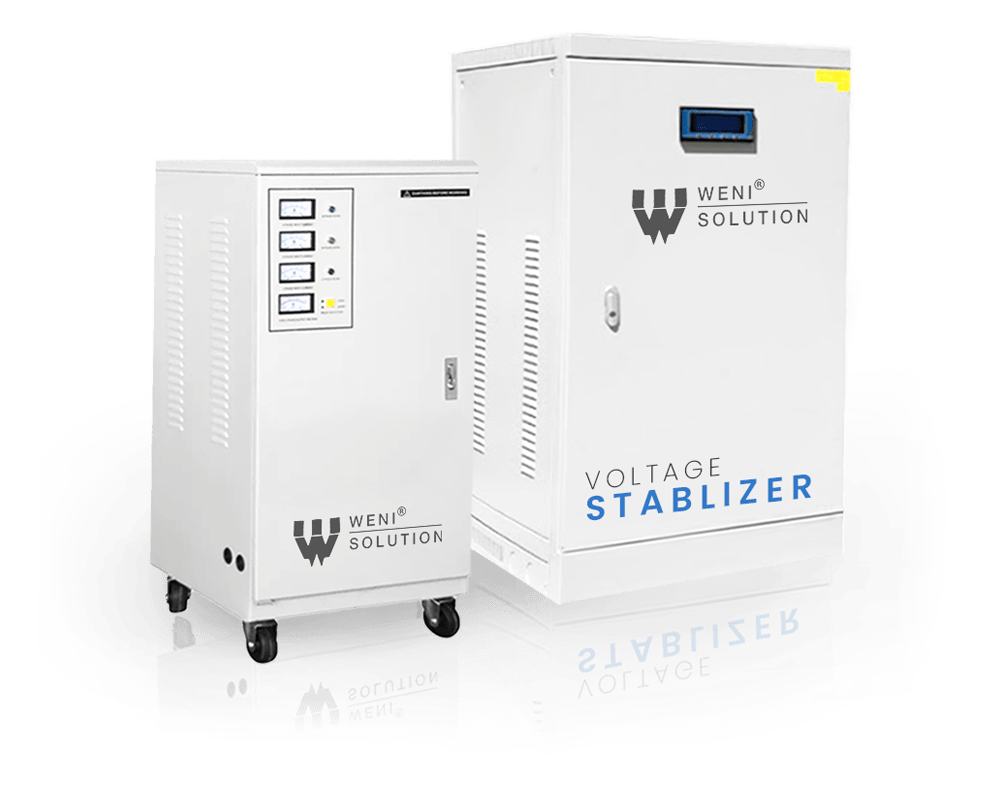

Apply a voltage stabilizer quickly it even eliminates long-term voltage drops thanks to the servos used.

In order for the cutting process to maintain quality, the laser cutter needs a stable mains voltage.

Large devices operating in the same network generate momentary voltage drops that may disrupt the operation of the laser.

Voltage drops can turn off the laser beam and waste material, and in extreme cases, damage the device.

To cut high-reflectivity materials such as copper, brass, gold, and silver, we recommend choosing an IPG laser generator. In the case of MAX PHOTONICS and RAYCUS, there is a high risk of generator failure/damage.

TubesT is a professional software for designing spherical parts like tubes and profiles dedicated to the TubePro 🛈 laser cutting system used in our equipment. It allows, among other things. on: drawing and modifying parts, as well as advanced, optimized Nesting and generating full process reports - everything you need to work with a pipe laser. As standard, a free lite version of TubesT, which has limited functionality, is added to the base Weni devices. The full (perpetual) version can be selected as an additional paid option.

The main distinguishing features of the program:

To cut high-reflectivity materials such as copper, brass, gold, and silver, we recommend choosing an IPG laser generator. In the case of MAX PHOTONICS and RAYCUS, there is a high risk of generator failure/damage.

Compressed air for the future?

Nitrogen is used as the shielding gas to cut stainless steel and non-ferrous metals. Since cutting requires high pressure, the gas consumption is also high. This results in high costs and some jobs being rejected as unprofitable. The solution is to use compressed air instead of nitrogen. Our efficient screw compressor (pressure 1.5MPa) makes it possible. Additionally, it is equipped with an air purification system, co provides protection of the optics of the laser head and cutting stability.

To cut high-reflectivity materials such as copper, brass, gold, and silver, we recommend choosing an IPG laser generator. In the case of MAX PHOTONICS and RAYCUS, there is a high risk of generator failure/damage.

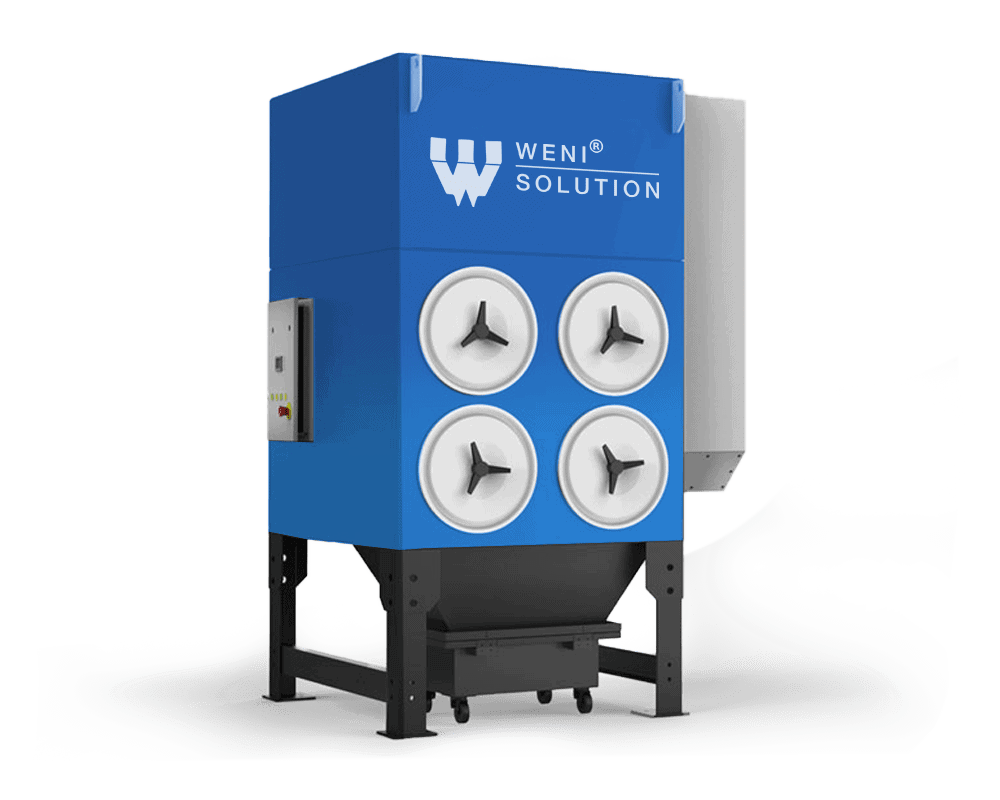

It is indispensable for production halls located close to housing estates.

Vapors and dust generated during the operation of a laser or plasma cutter are harmful to people and the environment. All our cutters are equipped with a basic exhaust extraction system. Its job is to extract the fumes from the working area and discharge them outside the building.

On the other hand, an additional exhaust gas filtration and extraction system cleans the air through special filters, eliminating harmful substances

In addition, energy savings are a huge advantage. Production halls require large outlays for heating. While the standard exhaust extractor can cool any hall in a short time, the filtration system returns warm and clean air back to the room.

To cut high-reflectivity materials such as copper, brass, gold, and silver, we recommend choosing an IPG laser generator. In the case of MAX PHOTONICS and RAYCUS, there is a high risk of generator failure/damage.

Ensure employee safetyespecially in rooms where many machines and people work simultaneously. After crossing the safety barrier, the laser stops working, preventing an accident during work.

To cut high-reflectivity materials such as copper, brass, gold, and silver, we recommend choosing an IPG laser generator. In the case of MAX PHOTONICS and RAYCUS, there is a high risk of generator failure/damage.

Order a special loading system and automate the process of cutting pipes and profiles.

The device independently loads the material onto the working field, which saves operators' time and significantly speeds up the cutting process. The maximum load capacity of the extension is as much as 3 tons, which is ideal for mass production. Control is via a touch panel, and an advanced signaling system ensures safe operation.

To cut high-reflectivity materials such as copper, brass, gold, and silver, we recommend choosing an IPG laser generator. In the case of MAX PHOTONICS and RAYCUS, there is a high risk of generator failure/damage.

To cut high-reflectivity materials such as copper, brass, gold, and silver, we recommend choosing an IPG laser generator. In the case of MAX PHOTONICS and RAYCUS, there is a high risk of generator failure/damage.

To cut high-reflectivity materials such as copper, brass, gold, and silver, we recommend choosing an IPG laser generator. In the case of MAX PHOTONICS and RAYCUS, there is a high risk of generator failure/damage.

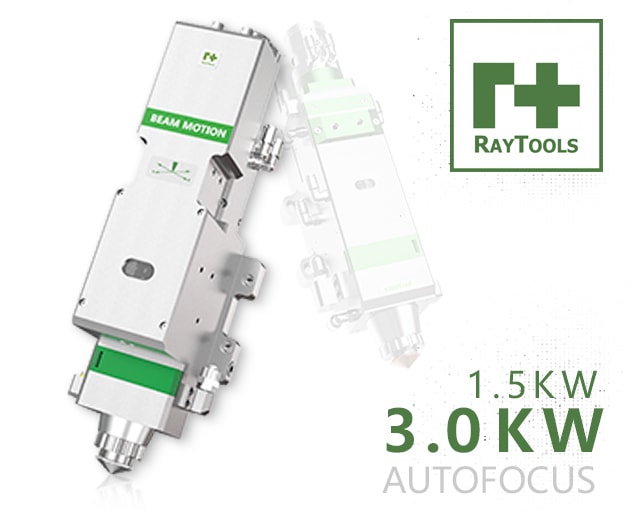

They are produced in Switzerland. The laser heads "RAYTOOLS AG" of the BM series are designed mainly for industrial applications. Designed for medium and high power fiber lasers. In our devices, we most often use the BM 109 1.5KW and BM111 3.3KW models.

A specialized dustproof housing prevents contamination of the collimating lens, which significantly increases its service life, and thus translates into the precision and efficiency of the laser beam. Optimization of the optical design and the water-cooled design enable stable and reliable operation of the laser heads in high-power devices.

The double safety design greatly increases the simplicity of the user when replacing the optics of the laser head, and the risk of contamination of the lens is almost zero. In addition, these heads are equipped with automatic focusing, which significantly improves the operation of the device.

Main features:

Positioning range up to 20mm

Compact, modular design

Highly efficient water cooling system

The ability to cut steel, non-ferrous metals and other highly reflective materials without fear of damaging the head

Various options for protective and focusing lenses

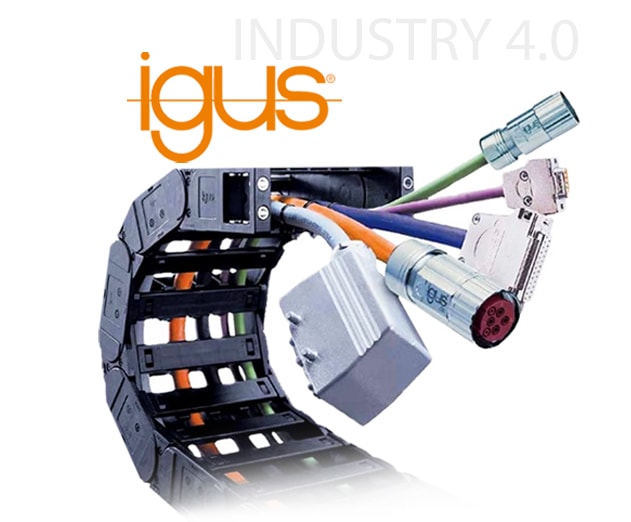

As an expert in energy chain systems, igus® has been supplying all components from a single source since 1964 - including cables. The technology and solutions developed and improved over the years by the German company igus® are unrivaled.

Contrary to the frequently offered spliceable cable options, igus® manufactures chainflex® cables based on the bundled principle. Motionplastic® technology is used in most professional devices on the market - we offer it as standard and use it in each of our devices.

Furthermore, igus® cables are covered by the manufacturer's lifetime warranty and are included in the price - with no hidden costs

The Schneider Electric range of Lexium servo drives includes AC LXM servo drives for use with BCH2 servo motors.

They are characterized mainly by:

• Reduced commissioning time

• Increasing profitability

• Improving efficiency

The latest generation of MachineStruxureTM from Schneider Electric is an intuitive machine automation solution with all the features you need to improve your productivity and your bottom line.

MachineStruxure is a complete solution for machine builders with benefits throughout the machine life cycle.

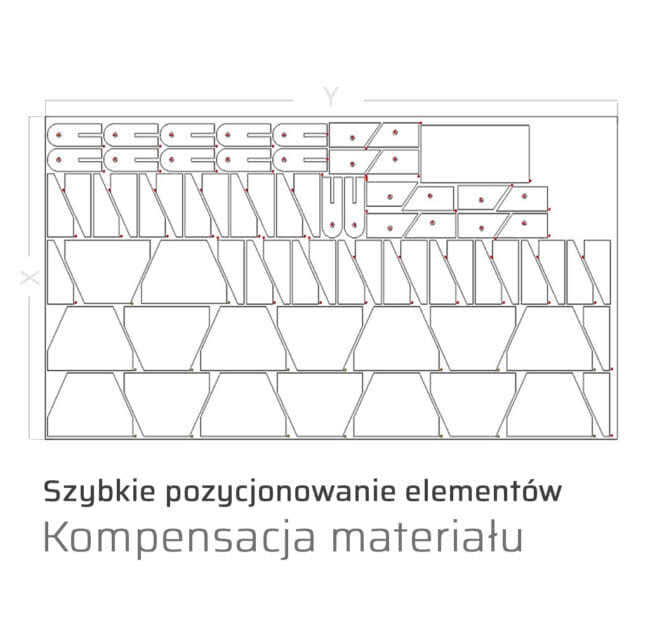

The nesting technology (Nested Based Manufacturing or NBM) significantly shortens and improves the production process, especially in the case of curved cuts.

Thanks to the possibility of positioning whole sheets of plates, it allows for better use of the raw material, i.e. reducing the amount of waste generated. Nesting enables optimal use of the material, and the cutting simulation function will allow for appropriate production planning / Production planning: Before the actual machining, the simulation function will determine the time needed to complete the task.

Wuhan Raycus Fiber Laser Technologies Co., Ltd. is a leader in the production of laser generators in the Asian market. Wuhan Raycus has an international team of specialists conducting development research, which allows the improvement and expansion of laser generators.

A great advantage of the company is the service and technical support department, and all repairs of devices take place directly at the customer's premises.

Raycus RFL series laser generators available from 500W to 12000W.

The TubePro laser cutting control system is a system software suite designed for spherical laser cutting. Includes laser cutting, common layout function and laser processing control. Most of its functions are cutting parameter settings, custom editing, simulation and control of the cutting process.

The TubePro software provided with the device enables:

Rail guides in our lasers are provided by three top manufacturers: PMI Linear Motion, HIWIN® and THK Global. They ensure high positioning accuracy, high repeatability and durability.

Linear guides ensure smooth movement of the trolley thanks to the use of rolling elements - balls or rollers. The difference between static and dynamic rolling friction is very small, so that the starting force is only slightly greater than the force supporting the movement. Therefore, stick-slip effects in Weni brand lasers do not occur.

The advanced cooling unit CW-6200 is a device designed to ensure the optimal operating temperature of both the generator and the laser head. Advanced automatics used in our units allow precise control of the coolant temperature.

The built-in alarm system informs the user about exceeding the permissible operating temperatures and about disturbances in the cooling liquid flow.

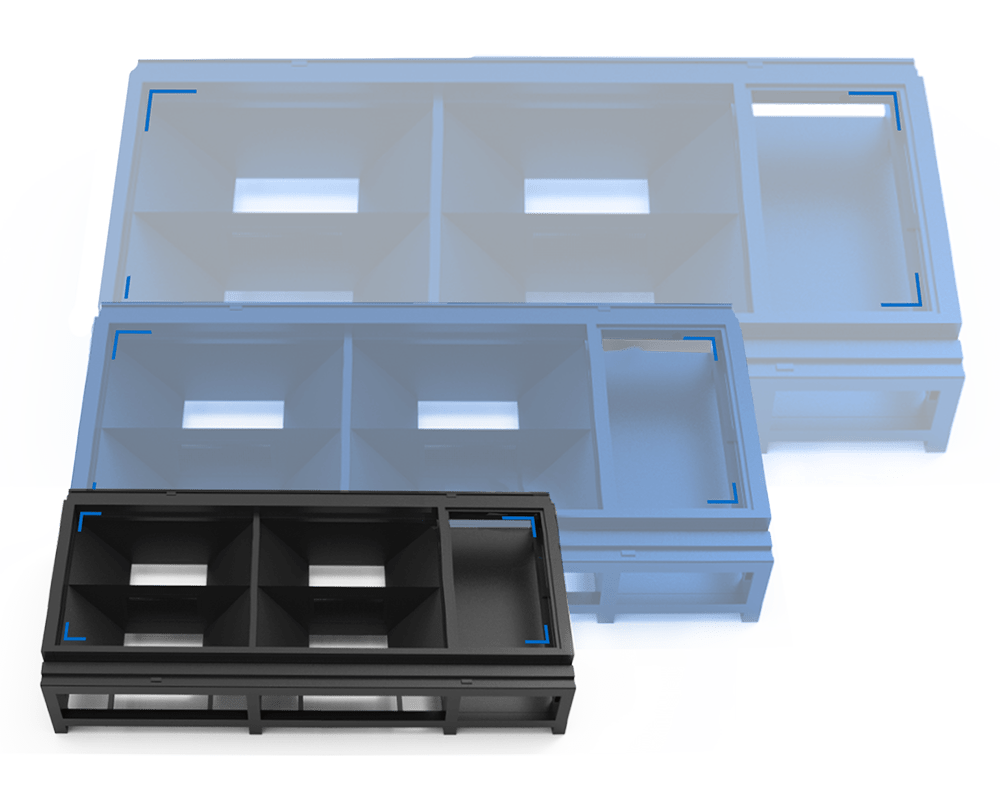

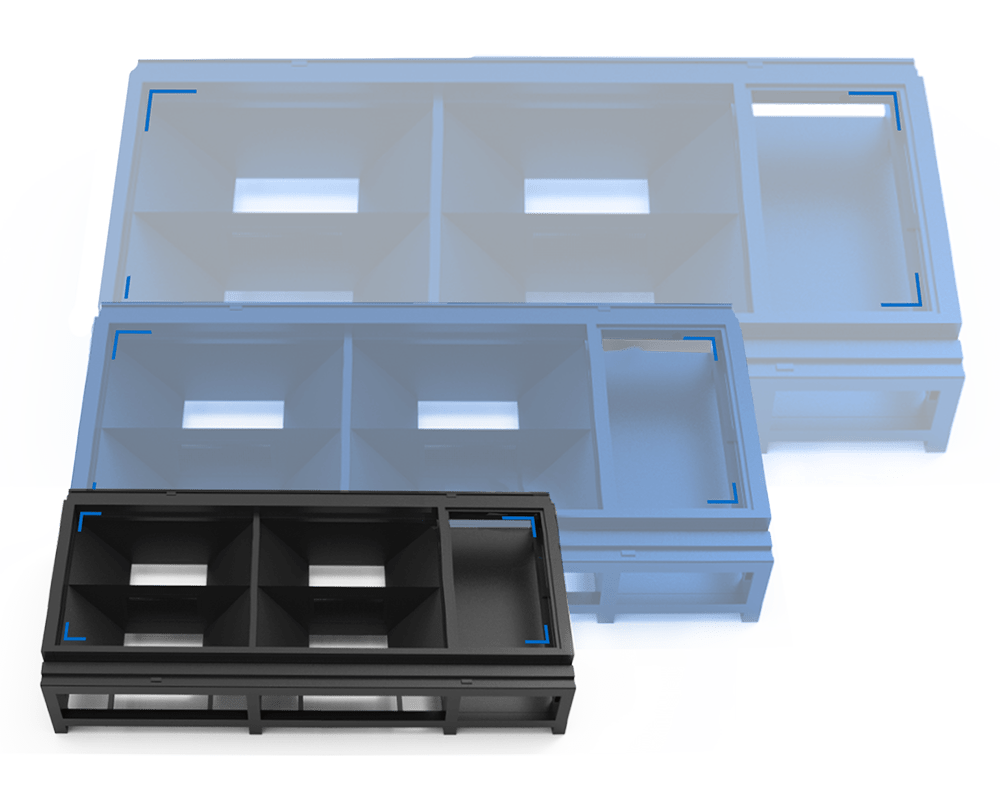

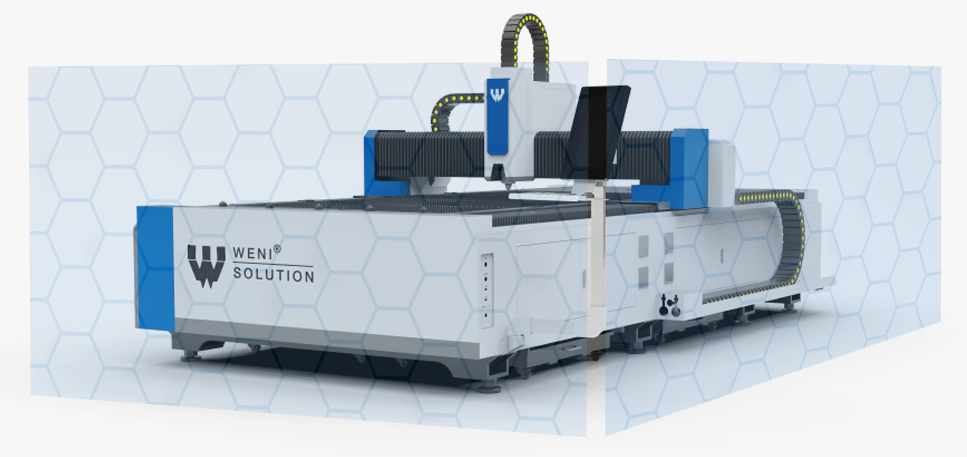

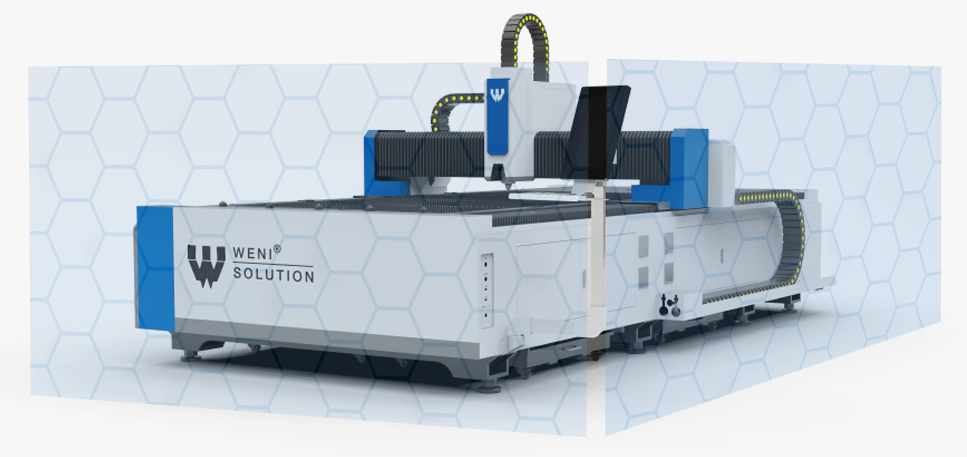

A specially designed new structure, made of high-quality steel, which guarantees maximum stability and even greater reduction of vibrations, which translates into the best cutting results. The frame is one-piece and in addition, despite its large size, it is light compared to other models, while maintaining the best parameters.

The welding process is carefully controlled and the position of the welds is well thought out to guarantee the longest service life of the device. The final step in building the structure is to subject it to thermal treatment, which increases its service life and strength.

Material:

Power:

Type:

„Parameters for the selected option will be added soon”

„The given parameters are illustrative and constitute an example of the selection of power to the thickness of the materials. They may differ from the actual parameters due to the processed material”

Note: For cutting highly reflective materials such as copper, brass, gold and silver, we recommend choosing the IPG laser generator (in the case of MAX PHOTONICS and RAYCUS, there is a high risk of failure/damage to the above-mentioned generators).