The second iteration of the best-selling model of the fiber optic cutter in our range, the WS-H PRO, is all about even better value for money. We achieved this by choosing brand-name components different from those we've used before, including a MAXPHOTONICS generator and the latest Yaskawa servo drives. With the facelift of the design, we have improved the design of the machine. The new 2nd generation of full body cutters is an increase in productivity while maintaining the highest cutting quality.

Now FREE bundled with the device:

To acquqire more details about the extras package, please contact our sales department.

See also the previous generation model:

The WS-H PRO series is also available in an extended version with:

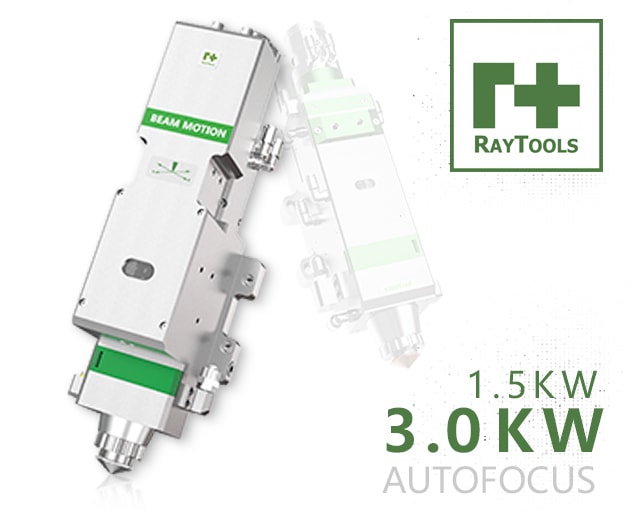

They are produced in Switzerland. The laser heads "RAYTOOLS AG" of the BM series are designed mainly for industrial applications. Designed for medium and high power fiber lasers. In our devices, we most often use the BM 109 1.5KW and BM111 3.3KW models.

A specialized dustproof housing prevents contamination of the collimating lens, which significantly increases its service life, and thus translates into the precision and efficiency of the laser beam. Optimization of the optical design and the water-cooled design enable stable and reliable operation of the laser heads in high-power devices.

The double safety design greatly increases the simplicity of the user when replacing the optics of the laser head, and the risk of contamination of the lens is almost zero. In addition, these heads are equipped with automatic focusing, which significantly improves the operation of the device.

Main features:

Positioning range up to 20mm

Compact, modular design

Highly efficient water cooling system

The ability to cut steel, non-ferrous metals and other highly reflective materials without fear of damaging the head

Various options for protective and focusing lenses

As an expert in energy chain systems, igus® has been supplying all components from a single source since 1964 - including cables. The technology and solutions developed and improved over the years by the German company igus® are unrivaled.

Contrary to the frequently offered spliceable cable options, igus® manufactures chainflex® cables based on the bundled principle. Motionplastic® technology is used in most professional devices on the market - we offer it as standard and use it in each of our devices.

Furthermore, igus® cables are covered by the manufacturer's lifetime warranty and are included in the price - with no hidden costs

YASKAWA Electric is one of the world's leading manufacturers in the field of drive technology, industrial automation and robotics, based in Kitakyushu, Japan.

Sigma-7 products set a new industry standard in servo capabilities with features that reinforce Yaskawa's 25-year reputation for redefining motion automation capabilities.Sigma-7 is a complete family of SERVOPACK servo motors and amplifiers from 3 to 15 kW that can be easily paired with a Yaskawa machine controller to create a motion automation system with the highest quality and reliability in the industry.

They are characterized mainly by:

- High efficiency, low heat emission

- Dimensions smaller by up to 20%

- High compatibility

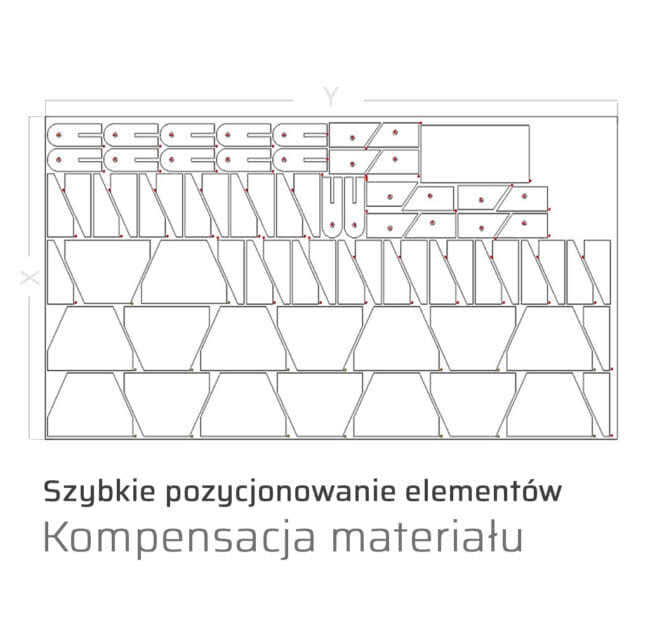

The nesting technology (Nested Based Manufacturing or NBM) significantly shortens and improves the production process, especially in the case of curved cuts.

Thanks to the possibility of positioning whole sheets of plates, it allows for better use of the raw material, i.e. reducing the amount of waste generated. Nesting enables optimal use of the material, and the cutting simulation function will allow for appropriate production planning / Production planning: Before the actual machining, the simulation function will determine the time needed to complete the task.

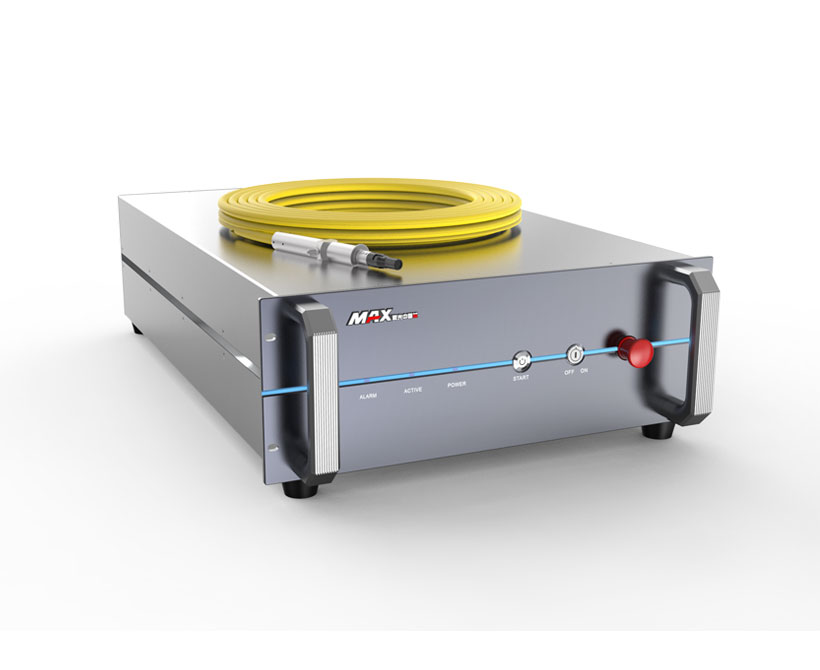

A new generation of 2000W-3000W single-mode fiber generators that combine high power, compact size, excellent beam quality and high light conversion efficiency. It meets all the requirements for precise beam processing.

In the new series, the ability to cut high-reflective materials has been improved. It is characterized by ideal high-frequency cutting. It can be quickly and conveniently integrated into machine tool equipment and large-scale industrial automation production line.

Product advantages:

1. more reliable and energy saving.

2. easy to maintain.

3. easy to use.

CypCut laser cutting control system is a system software set designed for flat laser cutting, including laser cutting, common system functions and laser processing control, most of its functions are used in graphics processing, parameter settings, custom editing of the cutting process, simulation and control of the cutting process.

The CypCut software delivered with the device enables:

In other words, a three-phase voltage regulator (AC) - it was designed to protect and ensure high-quality power supply to Weni Solution laser devices.

The basis for the correct operation of each laser is equal and constant voltage without interference. This significantly improves the quality of the cut and the efficiency of the laser generator.

Rail guides in our lasers are provided by three top manufacturers: PMI Linear Motion, HIWIN® and THK Global. They ensure high positioning accuracy, high repeatability and durability.

Linear guides ensure smooth movement of the trolley thanks to the use of rolling elements - balls or rollers. The difference between static and dynamic rolling friction is very small, so that the starting force is only slightly greater than the force supporting the movement. Therefore, stick-slip effects in Weni brand lasers do not occur.

Omron Corporation is a world leader in automation. Provides a variety of products and services in the field of industrial automation and electronic components.

Headquartered in Kyoto, Japan, Omron is headquartered in Kyoto, Singapore, Hong Kong, Amsterdam and Chicago and employs more than 37,000 people in 36 countries.

The advanced cooling unit CW-6200 is a device designed to ensure the optimal operating temperature of both the generator and the laser head. Advanced automatics used in our units allow precise control of the coolant temperature.

The built-in alarm system informs the user about exceeding the permissible operating temperatures and about disturbances in the cooling liquid flow.