Auxiliary gases have the biggest impact on the price of laser cutting services, as both their price and consumption are quite high. Initially, oxygen was the main and most popular gas, then nitrogen also gained popularity. An example of "expensive cutting" would be working on stainless steel or nonferrous metals, which require high-pressure gases - and that means more wear. For many years they looked for a cheaper alternative, until someone came up with an ingenious solution - cutting with compressed air (or rather, with its assistance), which consists mostly just of oxygen and nitrogen. It is much cheaper to obtain and can reduce cutting costs by as much as 16 times. It also has the added advantage of higher throughput and faster cutting, thereby measurably increasing productivity.

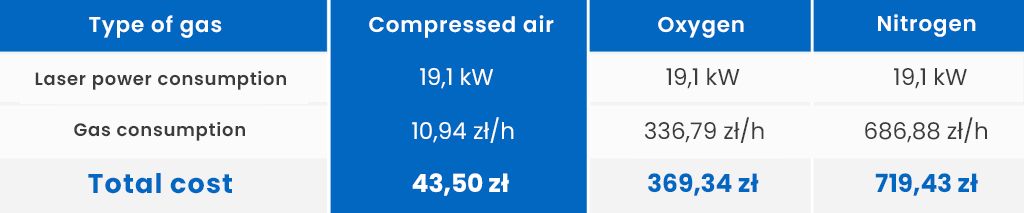

Below is a table created by the Weni Solution Technical Department to illustrate the savings.

Cost calculation for 1 hour of operation of fiber laser 3015H PRO with 3000W Raycus power:

Cutting parameters for stainless steel with a thickness of 3 mm. Costs of gas use - as of November 2022 in Opole province, approximate values.

The total cost of laser cutting with air support is 8 times lower than that of cutting with oxygen and as much as 16 times lower for cutting with nitrogen.

Taking gas consumption into account, air cutting saves up to PLN 650 per hour.

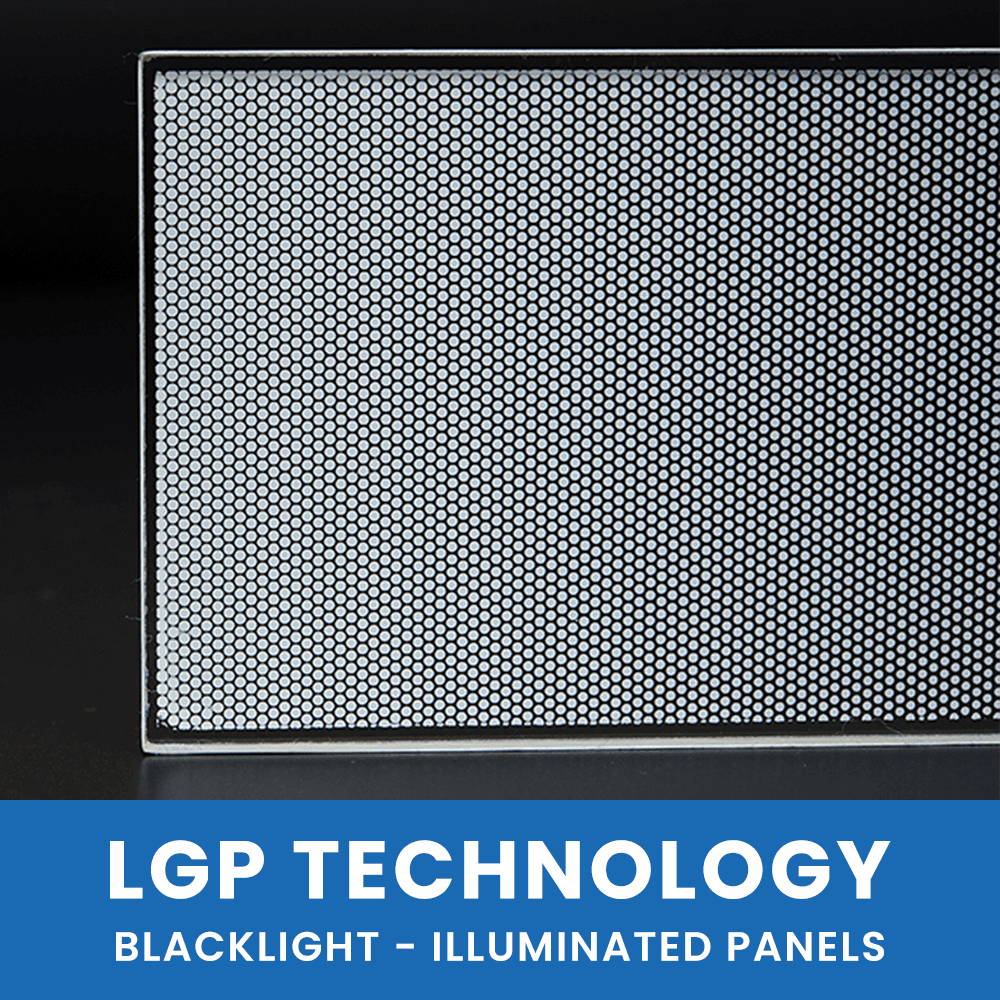

What does air cutting consist of?

The basic component of air is nitrogen (approx. 78%), which is used to cut non-ferrous metals, and oxygen (approx. 20%), which is used to cut carbon steel, which creates a fairly universal mixture of gases supporting the cutting process. The oxygen content enables the cutting process to be accelerated by up to 20-30% with appropriate selection of cutting parameters. Higher pressure and high nitrogen content in the mixture effectively remove molten material from the cutting edge.

What compressor to buy?

First of all, an efficient, quiet, screw compressor with a large capacity (min. 500l). We offer just such a model: Weni Compressor AC-20HP-500. The device complies with DIN ISO 8673.1 at the highest quality level of 1:1:1. This model is currently available from stock in our warehouse.

For air cutting, an ordinary compressor with a smaller capacity will not work, as the quality of air and the amount of pressure may not be sufficient to achieve a satisfactory result, and frequent switching will be cumbersome for operators. The compressed air supplied to the laser cutter must first of all be dry and very clean.

Does air cutting differ from working with traditional gases (O2, N2)?

The 20% oxygen content in the mixture increases the temperature at the cut edge, which in the case of e.g. stainless steel may cause minimal discoloration near the cut line. In some cases, additional processing of the cut elements is necessary. In addition, the edge of the processed material may be slightly worse, but for most customers this slight difference in quality is not a problem.

How has the price list for industrial gases changed in 2022?

In just a few months, the price of auxiliary gases has increased several times. As recently as February of this year, we made similar calculations. Back then, the cost of an hour's operation of a 3kW fiber laser for cutting 3mm stainless steel (taking into account gas and power consumption), was:

- 0.94 € with air (now 2.29 €),

- 12.44 € with oxygen (now 70.63 €),

- 20.84 € with nitrogen (now 144.05 €).

We can see a huge increase in charges for oxygen and nitrogen, while the cost of using compressed air is still much lower. In addition, let's pay attention to the price of the compressor, which has remained unchanged. At the beginning of the year we could save up to PLN 100 per hour using air, today it is up to PLN 650! Conclusion - cutting in the assistance of compressed air is even more profitable.

Will this solution work in every case?

According to our Service Department specialists - definitely yes!

Deciding to buy efficient 500l compressor you can take advantage of in many financing options. We offer favorable terms, such as leasing, or the option to repay in as little as 3 months. More details after contacting our financial specialist.

In conclusion, is it profitable to cut with air?

Despite the subtle difference in the quality of the cut line, which can be refined and given a higher quality, the air assisted cutting method is strongly cost-effective .

The cost of 1 hour of fiber laser operation using compressed air is 80% lower than using nitrogen. The reimbursement of the costs incurred for the purchase of a suitable compressor should pay for itself after just a few months.

Would you like to learn more about the air cutting method or Weni compressors?

Contact us:

a) By e-mail: [email protected]

b) By phone: +48 77 433 71 30 (Mon-Fri, 8:00-16:00)

c) Through the form available on our website