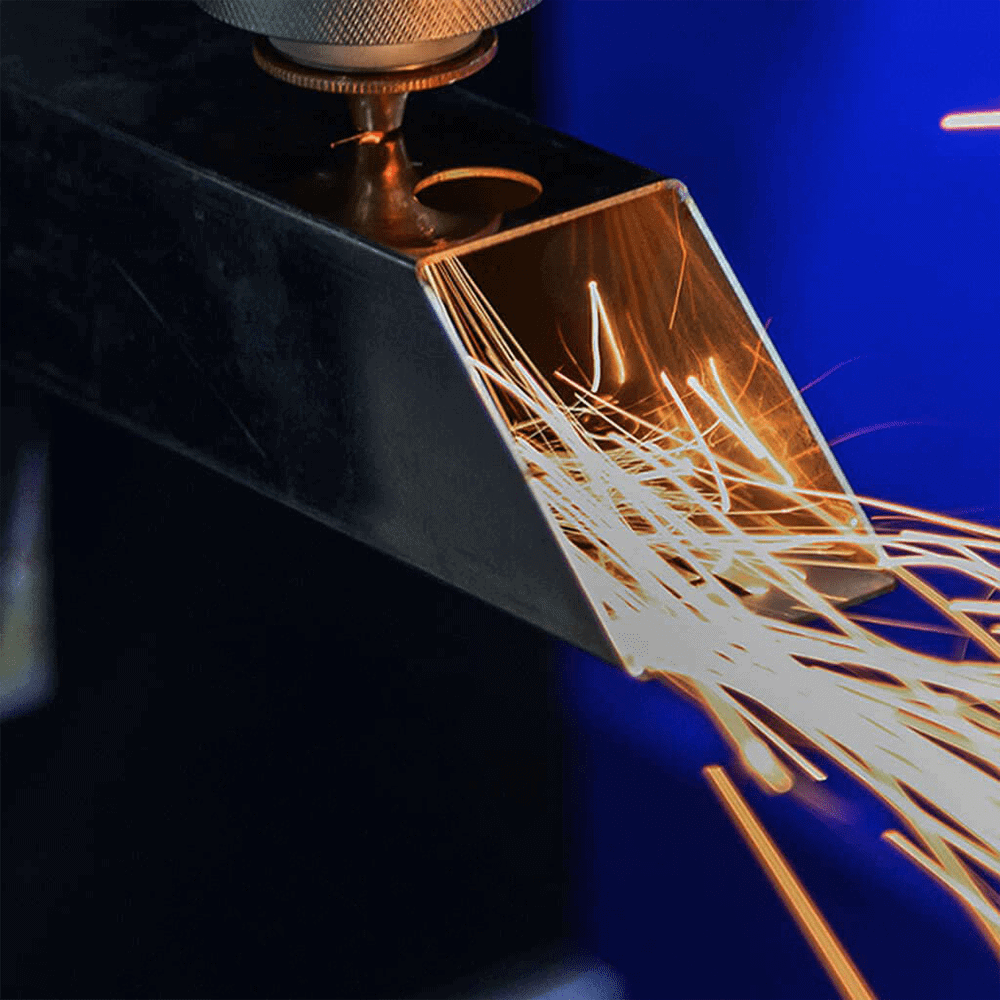

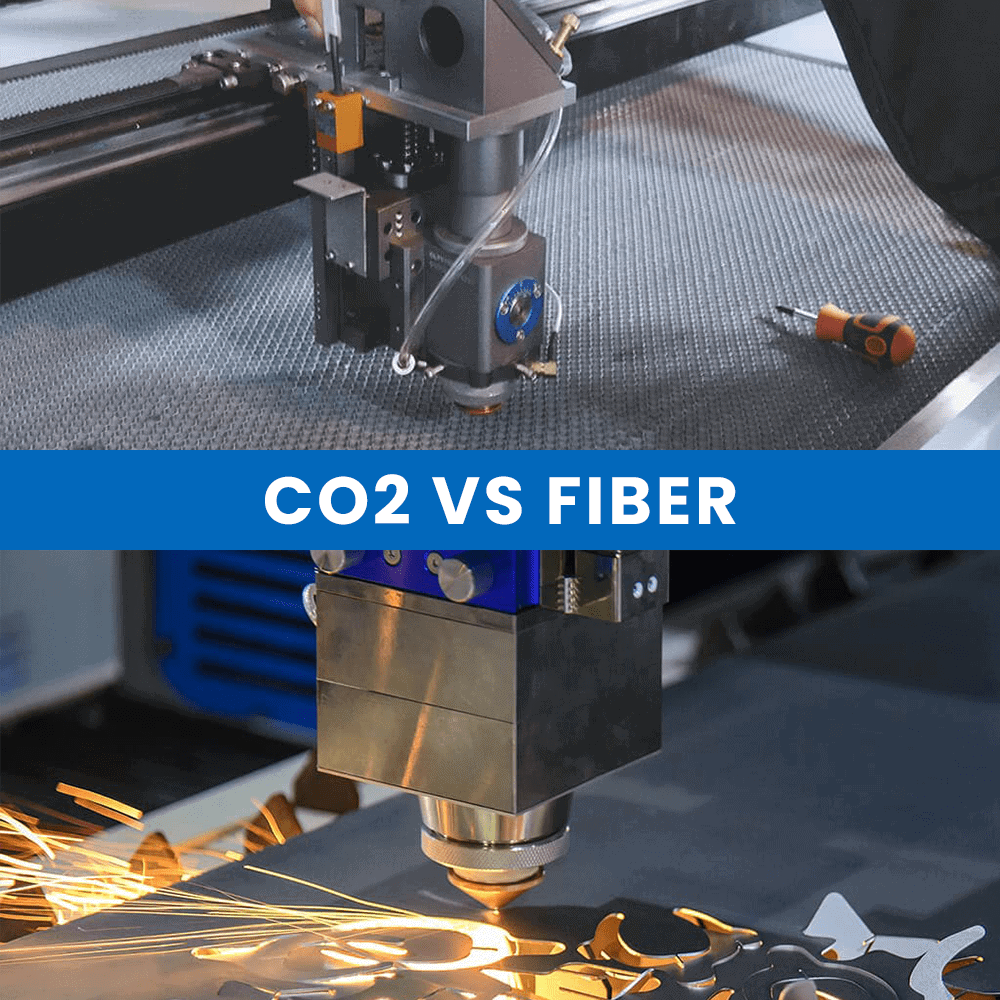

Laser cutting is the most modern and constantly improved method of processing metal materials. Fiber optic cutters they use technology that in many respects surpasses traditional methods, such as sawing or using a gas burner.

What are the most important advantages of fiber laser cutting?

First of all - PRECISION

The small size of the laser beam ensures high accuracy and precision of cutting. It allows for a perfect reconstruction of the design, making even the most complex shapes and patterns, which are problematic in traditional cutting.

Cutting with a laser beam provides a narrow area of thermal impact, which has a positive effect on the processed material. The metal maintains high quality, without distortions and unevenness, does not require additional processing and cleaning. The edges of the processed material remain smooth and maintain high quality.

Second - SPEED

The use of modern technology has significantly improved and accelerated the laser cutting process. Laser burners currently demonstrate lightning-fast speed. Optimizing the cutting process makes the device's working time significantly shortened, while still maintaining the best quality and precision of workmanship. The cutting speed and efficiency are incomparably better than traditional methods. In addition, working with the device is very convenient and does not require major preparations - all you need is a design and appropriate calibration.

Third, but no less important - REPEATABILITY

Full automation of the process guarantees perfect repeatability of movements. There is no risk of making a mistake or inaccurate reproduction of the design that could occur when the device is manually operated by a human.

The use of a laser plotter for metal provides great opportunities to work, even on the most complex, rich in details projects. The automatic laser ensures that the sketch is accurately transferred to the material being processed. In addition, the path of the laser beam is constantly corrected by the device itself, which prevents errors and minimizes material losses.

Is it profitable to buy a metal laser?

The numerous advantages of laser cutting make the purchase of a fiber optic cutter a profitable investment. In addition, it is an economical solution, because the equipment is durable and failure-free, and most consumable parts has a long service life. It is also worth emphasizing the versatility of the fiber laser - it can be used to process most types of steel, copper, aluminum and other metal alloys and sheets of various thickness. We are currently presenting many models, including in: WS-3015 GM with an accessory for cutting pipes and profiles . Offer in the tab "Available immediately" is updated on a regular basis so that you can choose the most appropriate device for your presentation or our materials.