1. Before starting the fiber laser (laser cutter), we recommend checking the condition of the protective lens, pay attention to whether there are any scratches, burns, dust or cracks on the lens.

2. Before starting to cut, make sure that:

- The pressure in the pneumatic system is not less than 7 bar.

- First raise the cutting head, then move it to the edge and make sure that the cutting elements are in the correct position.

- Perform process performance simulations to ensure that the cut sequence is correct.

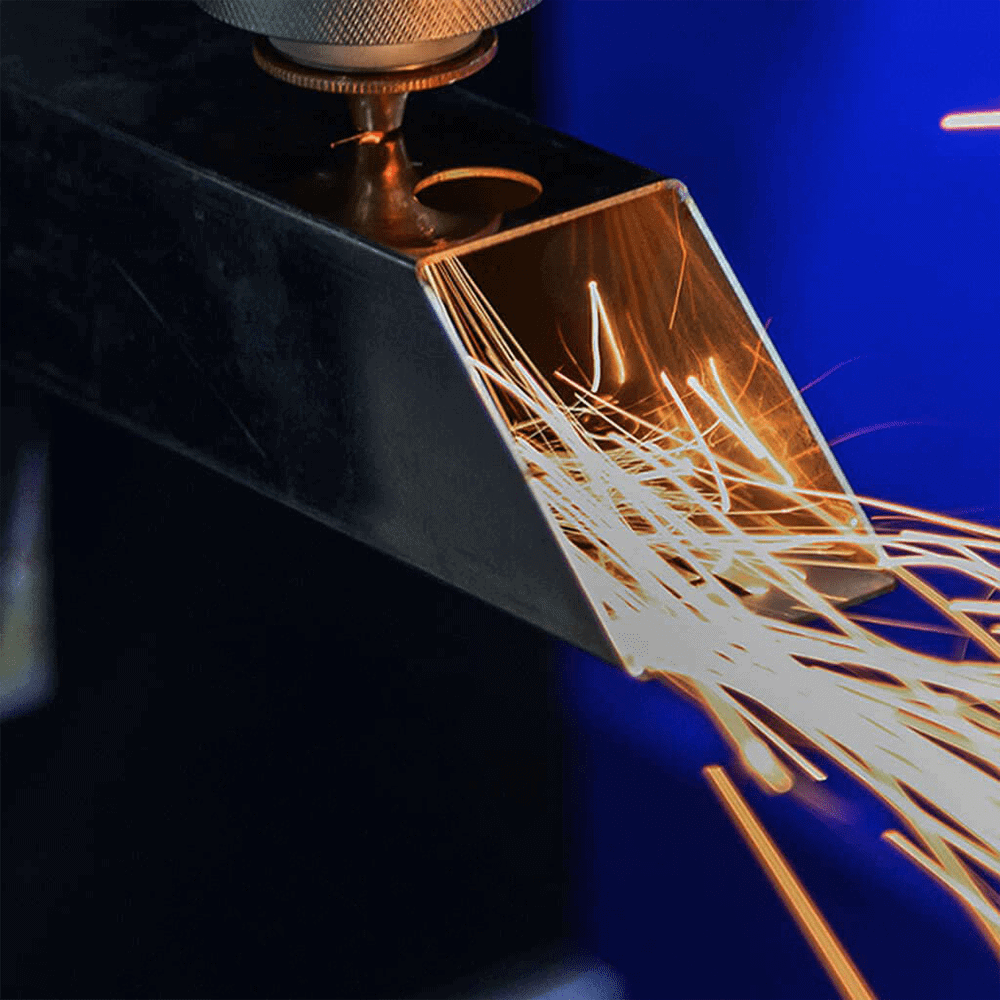

3. When cutting, it should be monitored that it is done properly. If not, you must first stop the process, manually raise the cutting head, then check that the cutting parameters are correctly selected and that the nozzle and safety lens are not damaged in any way. Then make the correct adjustments of these components and continue to monitor the operation.

4. When cutting, make sure that the element being cut has not changed its position on the working field. If so, remember to eliminate the collision points of the cutting head and the element.

5. It is recommended to clean the chiller monthly and to replace the distilled water once or twice a month.

6. It is worth cleaning the drawers for cut elements, because they collect a lot of filings and other debris.

7. Attention ! It is forbidden to look at the laser source and other points where the laser causes reflection while the device is operating.

| The frequency of the activities performed | Elements of the device to be checked | Steps to be performed |

| Every day | Worktable | Cleaning from cutting residues |

| Every day | Wires | Check that no wire is broken or broken |

| Every day | Fans | Checking if all fans are working properly (also in the control box) |

| Weekly | Guides | Check that the lubricant is applied correctly, that there are no leaks and that the guides are not crooked |

| Occasionally | On-board computer | Check the system with an antivirus program |

| Once a week (or as needed) | Protective lens | Checking if the lens is dirty and cleaning it |

| Occasionally | Extraction and water connection | Make sure that the water connections made and that the flue gas exhaust is properly interrupted and that it is efficient |